We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Polypropylene PP Recycling – Challenges and Solutions for Plastic Recycling

1__25F170Dr4j.jpg)

The Challenges and Opportunities of PP Recycling

- Contamination and Moisture: PP waste may be mixed with other plastics, dirt, food residues, or moisture, making it challenging to process.

- Material Degradation: Traditional recycling methods may degrade the material, affecting the quality and mechanical properties of the recycled PP pellets.

- Diverse Waste Streams: PP comes in various forms, from thin films and woven bags to rigid containers and lumps, each requiring a specific approach.

- Efficiency vs High Processing Cost: Ensuring consistent and high-quality output while maintaining energy efficiency is crucial for profitability.

Despite these challenges, the demand for recycled PP is on the rise. The new regulations, Extended Producer Responsibility (EPR), and the sustainable practices for the circular economy principles lead the industry to recycle more plastic waste, including PP waste. This creates a significant opportunity for businesses equipped with the right recycling equipment and technology.

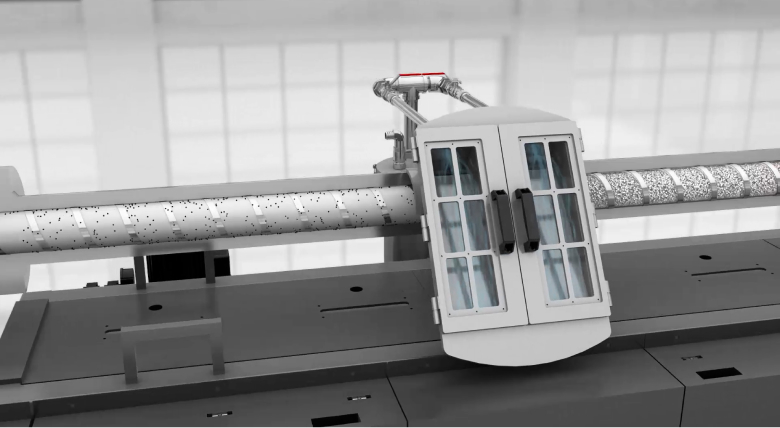

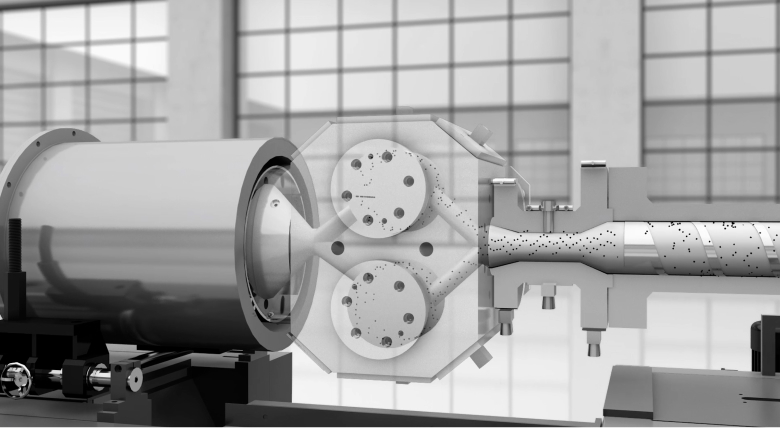

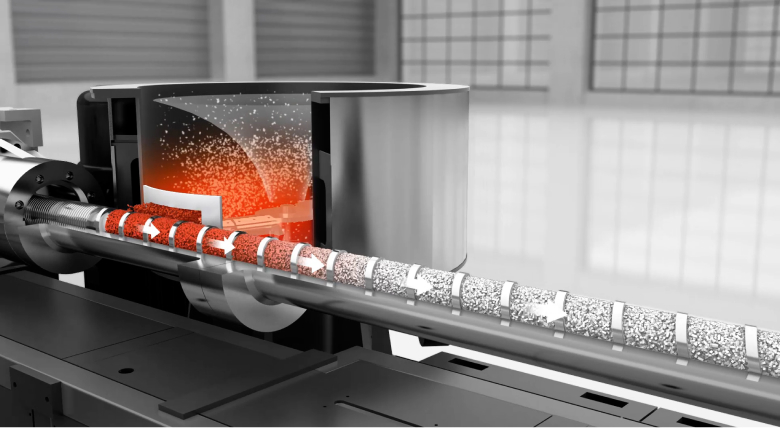

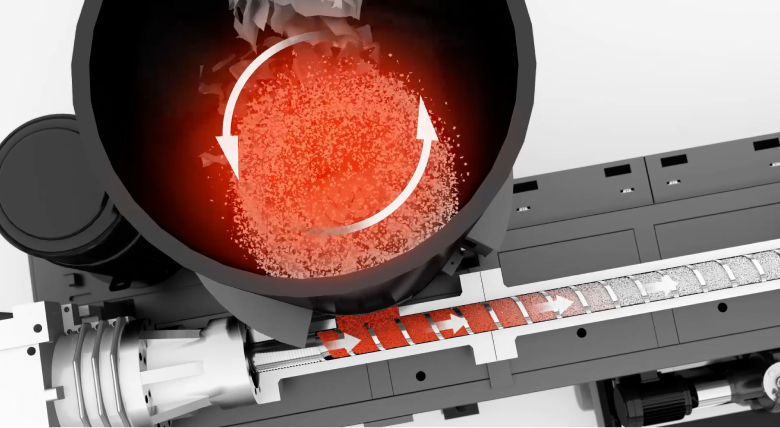

How POLYSTAR's Plastic Recycling Machines Overcome the Recycling Challenges

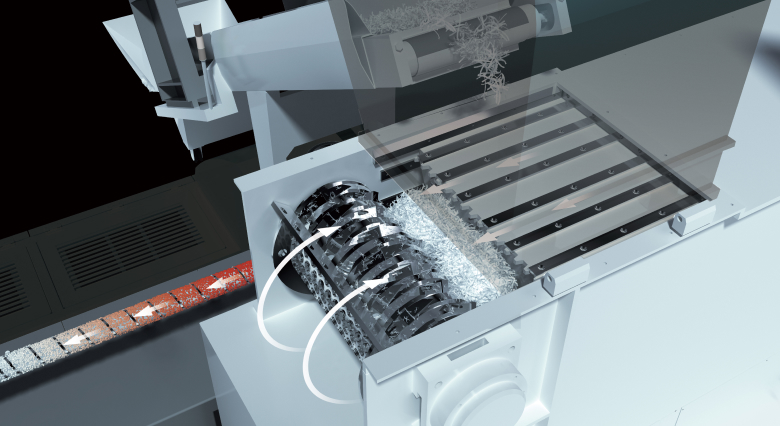

1. Advanced Handling of Contamination and Moisture

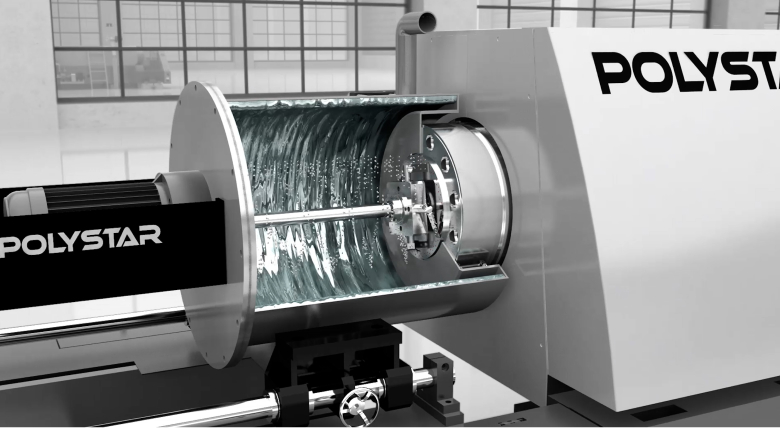

2. Preserving Material Quality and Properties

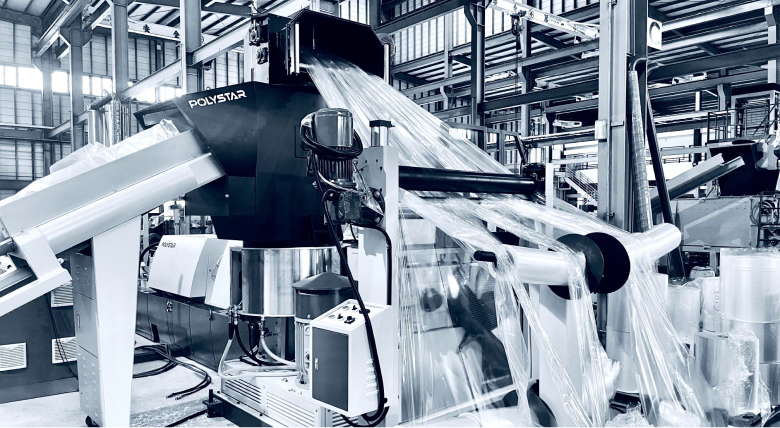

3. Efficiently Processing Diverse Waste Streams

4. Delivering High-Quality Recycled Pellets

- New films and bags

- Injection molded products

- Pipes and profiles

- Woven fabrics and tapes with excellent tensile strength

Conclusion

Read More

About the Author

Resul Gökpınar

International SalesResul creates up-to-date content based on his experience, gained by solving customers' problems in Turkey and the EMEA market.