We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

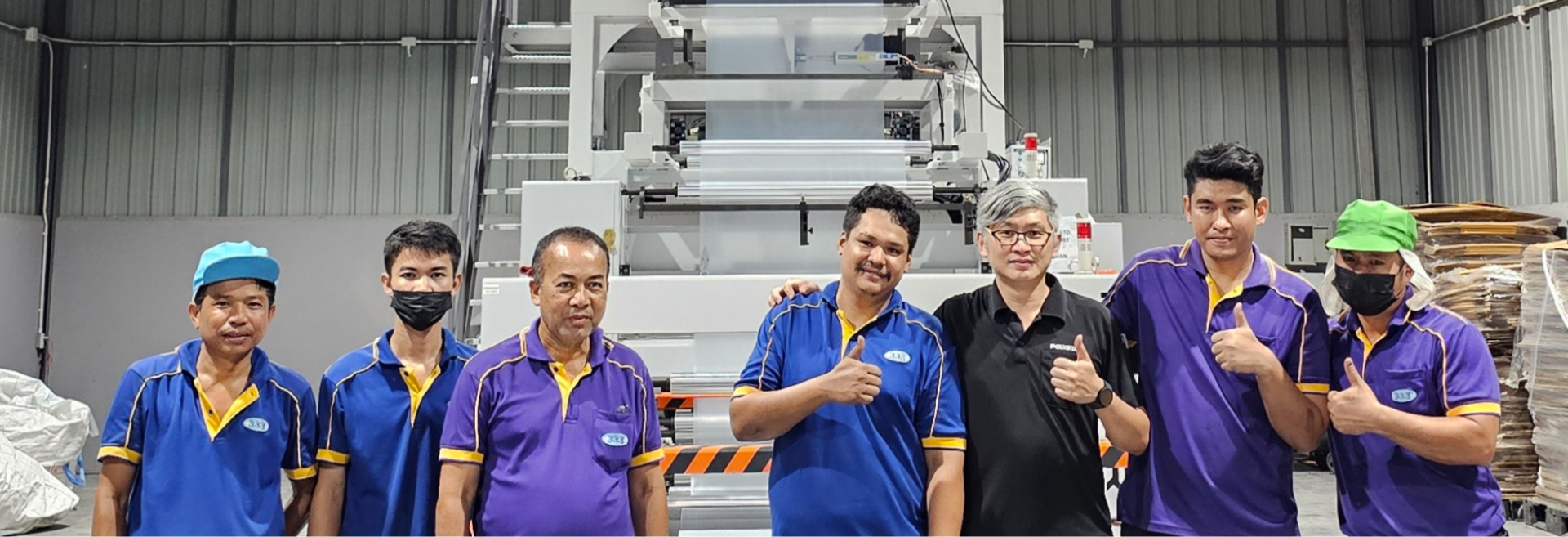

From Bottled Water to Shrink Film Manufacturing: A Thai Success Story with Komgrich 333

The installation and training process went smoothly, exceeding the customer’s expectations.

This feedback speaks volumes about the user-friendly design and intuitive operation of the blow film machine, as well as the effectiveness of the training. Inspiring the customer to take control of their packaging production was key to the project’s success.

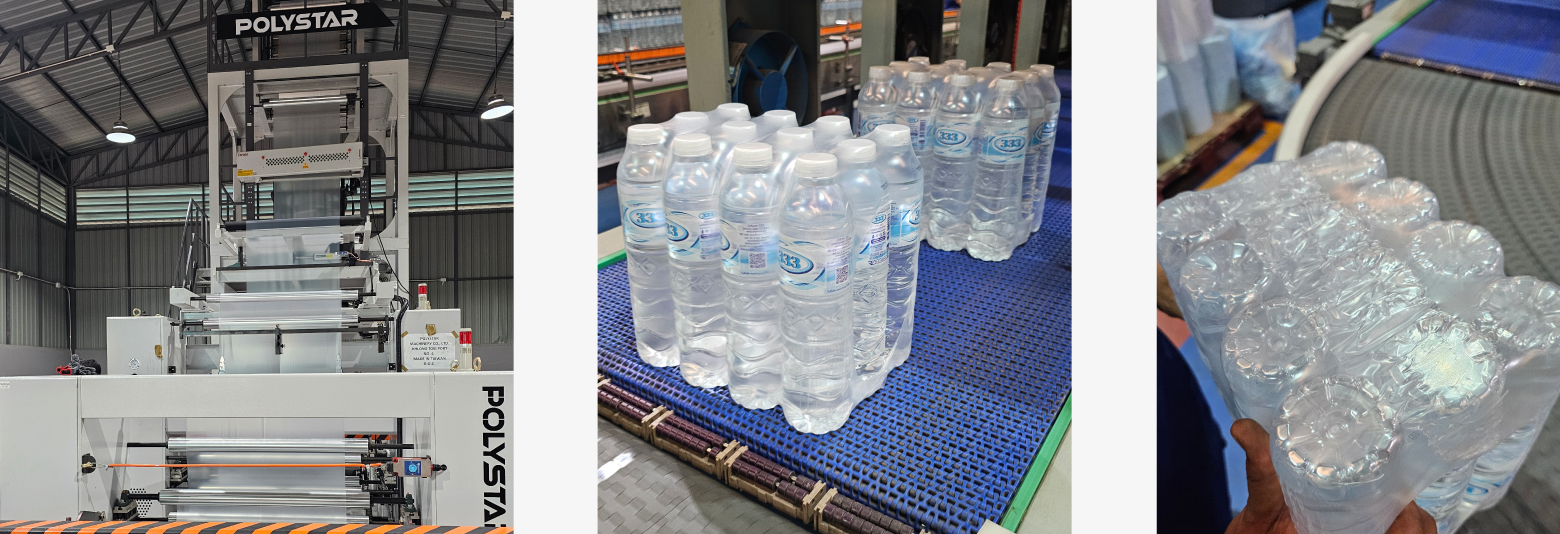

Now, instead of relying on third-party suppliers, the Thai bottler produces its high-quality shrink film, personalized specifically to their needs.

Key Advantages of In-House Shrink Film Production

1. Cost Savings: Eliminating the middleman translates to significant cost reductions in packaging materials. They now have full control of their production costs and the ability to optimize plastic material usage to minimize waste.

2. Quality Control: Producing their film allows for careful control over the quality and specifications of the shrink wrap. They can now ensure the film’s strength, clarity, and thickness that meet your exact requirements for optimal bottle packaging.

3. Supply Chain Security: No more worrying about supply troubles or fluctuating prices. The Thai customer has a stable and reliable source of shrink film, ensuring their smooth operation.

4. Flexibility and Customization: This allows greater flexibility in packaging design and customization. Now, they can easily adjust film thickness or add branding elements as needed.

5. Sustainability: Better ways to handle waste and the potential of exploring more environmentally friendly film materials are two benefits of in-house production that can meet the rising demand from consumers for eco-friendly packaging.

The success story of this Thai Bottled water company highlights the value and knowledge that POLYSTAR brings to its customers. By providing not just a machine but also a well-prepared installation, training, and ongoing support from the whole team.

POLYSTAR helps businesses to transform their operations and achieve greater efficiency, cost-effectiveness, and sustainability. This installation is an example of how POLYSTAR is helping businesses succeed.

Read More

- A Leading Cement Manufacturer in Pakistan Transforms Waste into Reusable Resources with POLYSTAR’s Pelletizing Machine - Customer Stories

- Türkiye – Em Plastik Achieves Efficient Waste Management in Its Factory with POLYSTAR Pelletizer - Customer Stories

- E.I.G. CO., LTD Boosting Production and Sustainability in Vietnam with POLYSTAR - Customer Stories