We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

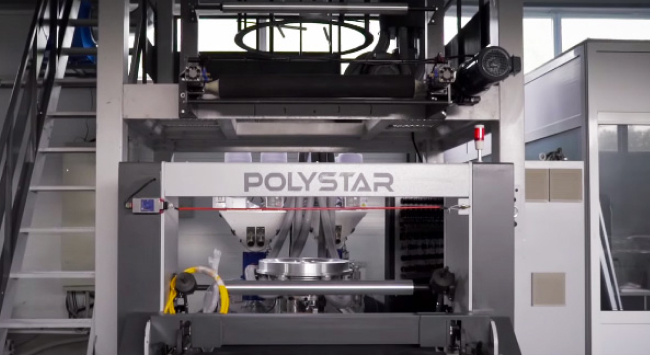

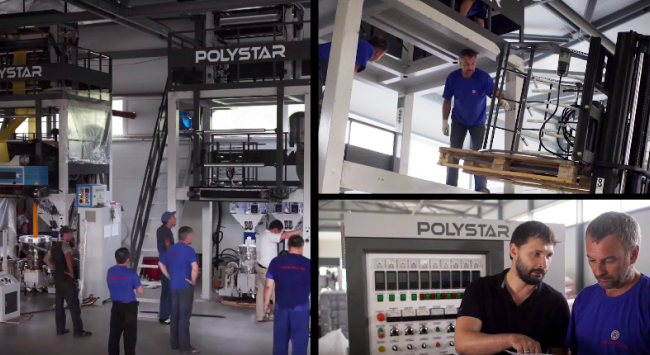

ABA 3 Layer Co-Extrusion Blown Film Extruder Eco-X

__23L01KQUgT.jpg)

ABA Blown Film Technology: Thinner, Stronger Film at Lower Production Cost

The Main Advantages of the ABA Line are:

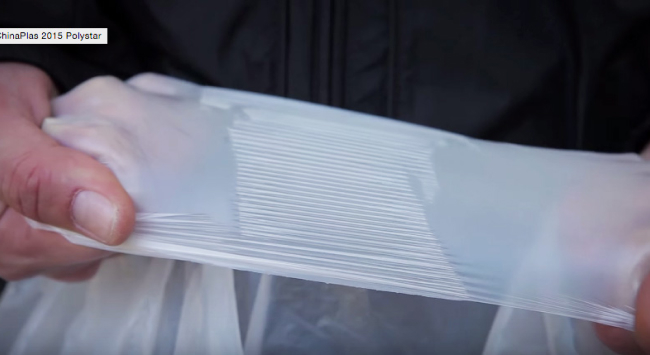

- Stronger, higher film resistance compared to mono-layer film products with the same thickness

- Cost saving: Virgin material is applied mainly on the outer (thin) layers which is relatively a very small percentage of the film composition

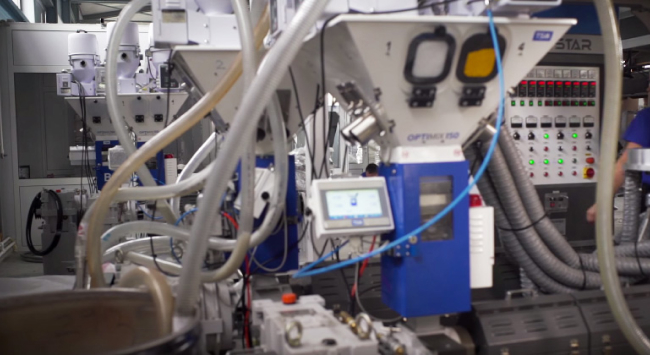

- Better material mixing with co-extrusion to produce better-quality film

The Main Usage and Applications of the ABA Machines are:

- For the production of T-shirt bags, garbage bags, and shrink film (for bottle wrapping

- 60% CaC3 compounds or recycled material can be used in the middle layer

- Thin outer layers with virgin material to cover the film surface so that it still looks good and shiny despite the usage of secondary-grade material in the middle layer