We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

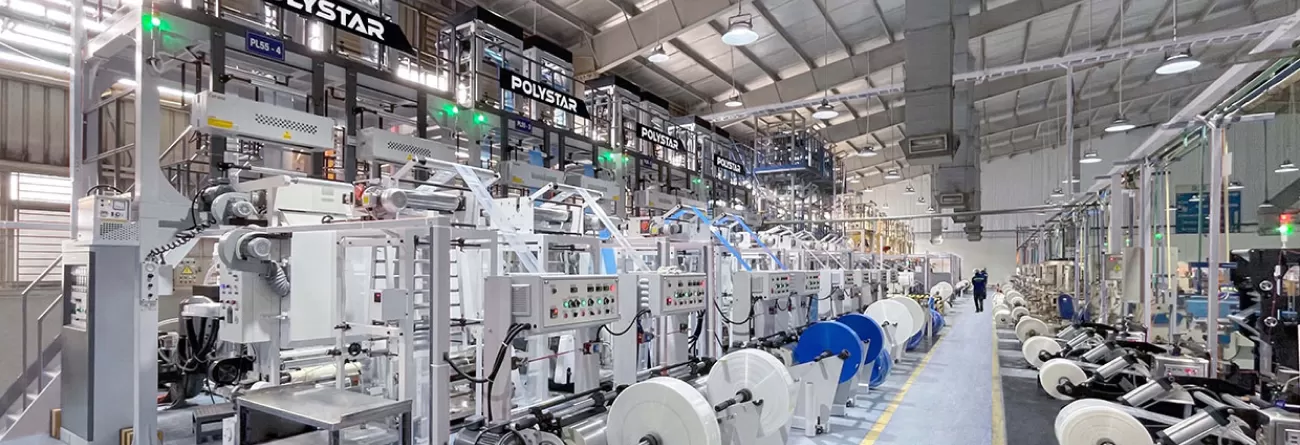

Film Extruder with Twin Head – Efficient For Bag Production?

Small Bags. Big Production.

Higher production for thin film and small-sized bags.

Compared to extruders with single die heads, the double-die extruders can achieve higher production capacity when producing film rolls that are small in width, as the high extrusion output is dispersed into two separate channels of the die heads instead of one.Designed for HD/LDPE Bag Producers.

Productive for All sizes.

Flexible in production.

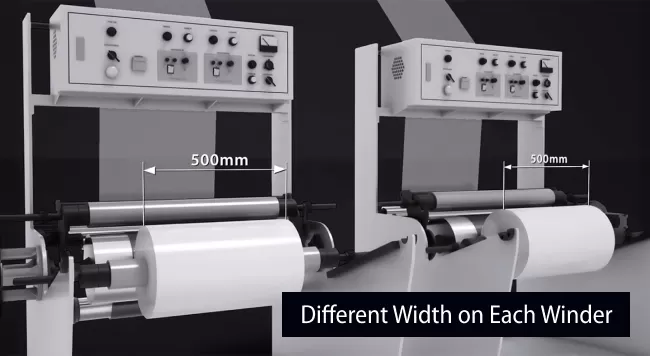

The ability to produce different film widths and thicknesses on each winder at the same time also adds flexibility to the production.

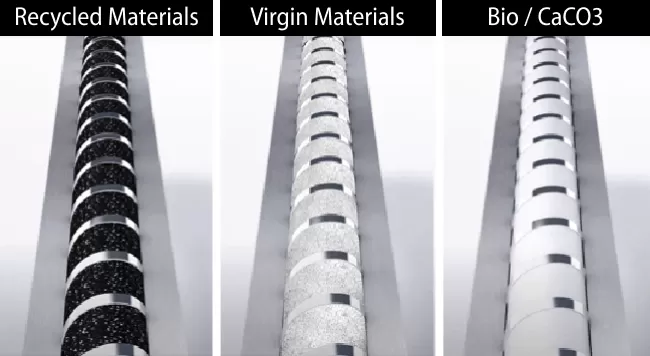

Works with Different Materials.

Recycled, Virgin, CaCO3, biodegradable.

Operator-friendly Design.

( Every control panel is positioned at the most convenient location for operators to run the machine in a simple way. )

Precise Control. Stable Production.

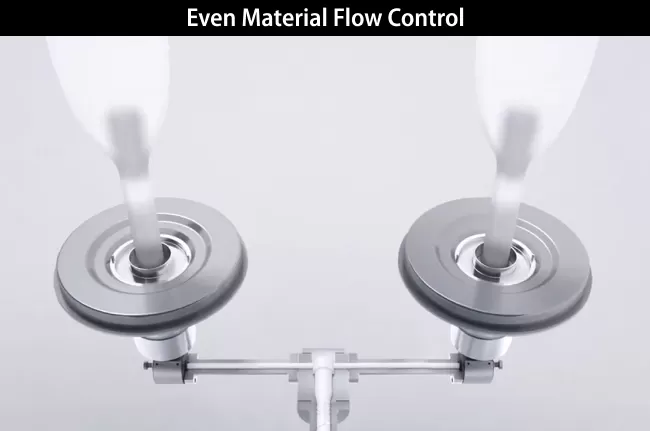

Even Material Flow

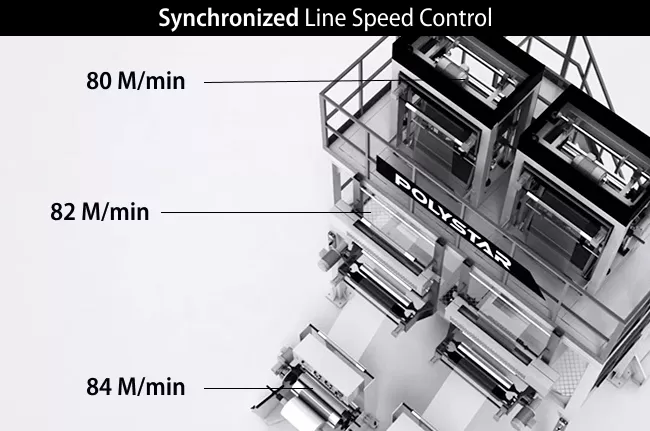

The material going into the two die heads from the extruder is precisely controlled, thanks to accurate temperature control throughout the entire production process. This ensures even output on both die heads for stable operation. The line speed between the take-up and winding rollers is synchronized for easy machine start-up and speed/size adjustments.World-class Components.

Maximum performance. Minimum consumption.

Stable operation and low power consumption are the most important factors for plastic producers. We have, therefore, equipped our machines with top-quality electrical components and energy-saving motors to minimize machine downtime and energy consumption.

Fast Delivery. Simple Installation.

A standard Duo-X 55-750 can be delivered from Taiwan within 30 days

About the Author

Jack Lin

Sales ManagerJack has visited and spoken to hundreds of POLYSTAR machine users around the world over the last 10 years. Having collected practical information on customer feedback and user experiences, he enjoys sharing the advantages and disadvantages of using different types of machines with others, especially coming from the customers' perspectives.

__23L12QJh00.webp)