We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Sweden Post-Consumer Recycler - Intelligent Recycling with POLYSTAR Repro-Direct

The Sweden-reputed recycler, which is the professional recycler collects plastics from waste electrical and electronic equipment (WEEE) and other products from the automotive sector such as bumpers, battery packs, engine piping, etc.

These post-consumer wastes contain iron particles, wood pieces, paper labels…etc. Thus, the turnkey solution from the material sorting, cleaning, drying, and processing into the high-end quality recycled pellets are the essential factors toward business success.

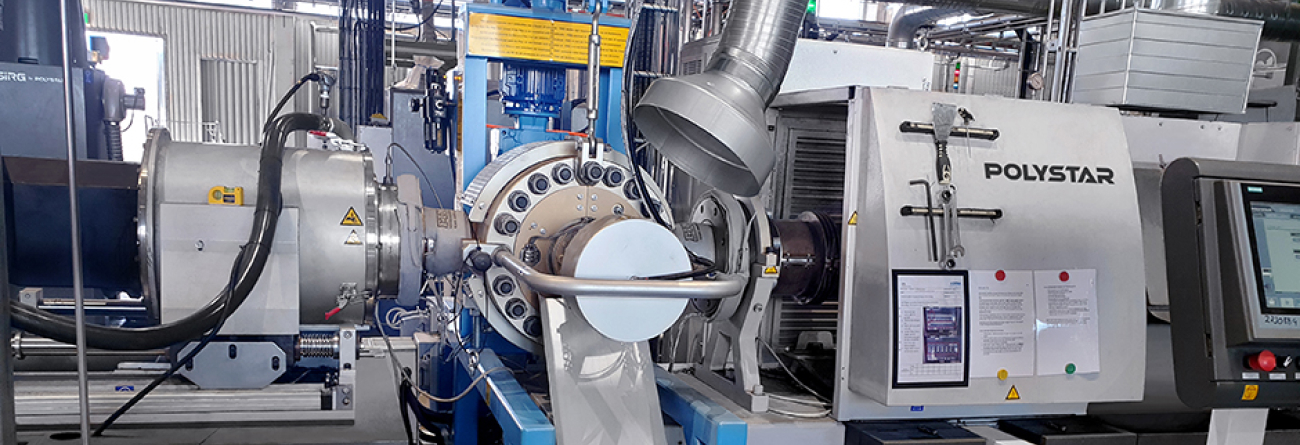

Thanks to the simplest yet powerful design of POLYSTAR’s recycling machine, plus integration with FIMIC’s advanced auto-cleaning filtration system. It ensures excellent filtration efficiency and continuously high output performance.

The collected post-consumer ABS and PS regrind have a higher bulk density of 200-600 kg/m3 and have more fluidity.

Both properties contribute to the washing and sorting processes working better and the material thus being available in a more clean-sorted form. Meanwhile, POLYSTAR customizes the tailor-made screw profile design which is optimized the melting flow paths and activities for both materials, and the specific pelletizing die head design is also beneficial for stabilizing the quality and consistency of the pelletizing process.

Moreover, the customer requests the intelligent water level sensing control on the vibration tank to optimize the cooling efficiency in time.

With POLYSTAR's simplified and user-friendly structure design, the cooling temperature can be visibly monitored and controlled via an intelligent PLC control system, the average output of its Repro Direct 150 reached up to 700~800 kg/hr for our business benefit constant contribution, impressively described by the factory director.

As a professional recycler in the post-consumer recycling industry, the excellent quality of the plastic recycled pellets and the high efficiency of machinery operation are the most important two indicators we pursue.

Hence, we consider that the simplest yet most powerful machine of POLYSTAR, and its high degree of fully automated control system can be met with our expectations, says the customer.

By adopting SIEMENS state-of-the-art PLC plus POLYSTAR intelligent HMI touch panel control system, the energy and current consumption can be monitored in time, and the feeding, cutter compacting, extrusion, filtration, pelletizing units are flexible switched control and data setting precisely. The other value-added functionality of this smart PLC control system is as below:

- Preheating sequence of the extruder temperature for a higher degree of automation.

- Process parameter data setting, recording and simulation

- Operation data curve analysis

- Operation error alarm and in-time report

After a comparison of several advanced melt filter solutions by the client itself, they finally chose the Italian FIMIC auto-cleaning filtration system as the cost-effective solution.

Thanks to the similar “ Simple yet Powerful” design concept and mentality of FIMIC. It can be perfectly integrated with POLYSTAR's recycling line and perform the best filtration capability via mutual technical cooperation.

The major advantage and core values of the FIMIC auto-cleaning filtration system is indicated below:

- Lower Sensitivity: The scraper collects immediately the contaminations from the screen and avoids the contamination permanence or damage to the screen.

- Lower Maintenance Cost: The cost of spare parts is approximately 5 times less expensive than other suppliers.

- Easier Operation: Simplified configuration structure design, needs only 30 minutes and one operator to replace a screen efficiently.

- Less Production Loss: As a general rule, the max. melt losses with FIMIC technology only reach to 0,5% - 1%.

- Specific Valve Discharging Technology: The valve can be automatically adjusted according to the amount of contamination accumulated, to ensure the maximum clean melt material kept inside.

After converting the home appliance waste into recycled pellets, the degree of degradation is a major concern.