We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

How to Reprocess Highly Printed Films? PE, PP, BOPP

The laws toward plastic have become stricter, which require the producers to use a higher percentage of recycled material in their final products. The benefits of these laws are lowering the production cost of the producers and reducing the plastic waste in our environment.

New Standards for Plastic Pellets

Plastic producers and professional recyclers started to pay more attention to products that could be recycled but were difficult to reprocess.

Here are the examples:

- Highly printed film (PE and PP)

- Flexible packaging

- Laminated film

- Multilayer film

- BOPP film

Why Should you Reconsider a Two-stage Recycling Machine?

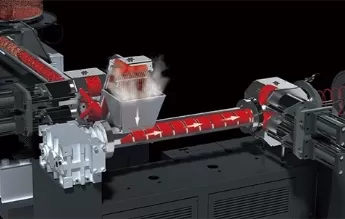

POLYSTAR, through reengineering, designed the perfect solution: Repro-Flex Plus

Repro-Flex Plus is able to reprocess the highly printed material and improve the quality and productivity of the recycled pellets. With a two-stage recycling system, two filtration and three degassing steps ensure the minimal degradation of the material, which produces uniform pellets for reprocessing directly into your production line.

Simple in Design. Simple in Operation.

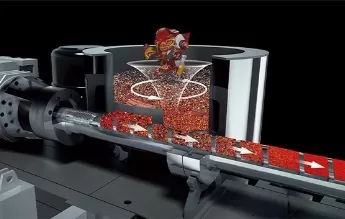

Cutter Compactor

This cutter integrated pelletizing system eliminates the necessity of pre-cutting the material, because the cutter-compactor pre-cuts, pre-warm and mix the material that will be feed directly into the extruder with a centrifugal force.

Tripe Degassing

Higher Capacity and Cost Reduction.

Finally, POLYSTAR offers not only simple solutions for plastic producers, but also instant after-sales services. What’s more, Polystar has agents and technicians around the globe. These representatives specialized in POLYSTAR Machines, giving machine installations and after-sales as well.