We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

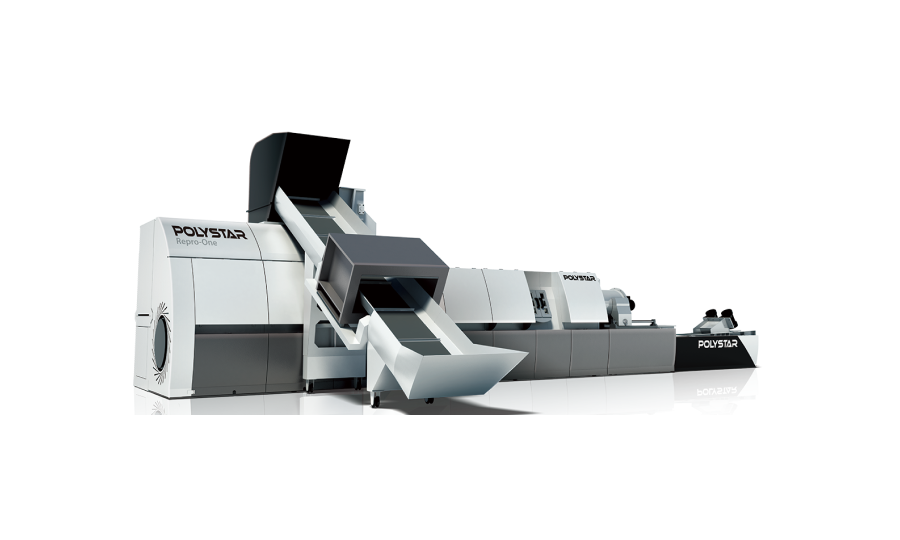

Shredder Integrated Plastic Recycling Machine

One-step Process. Lower Material Degradation

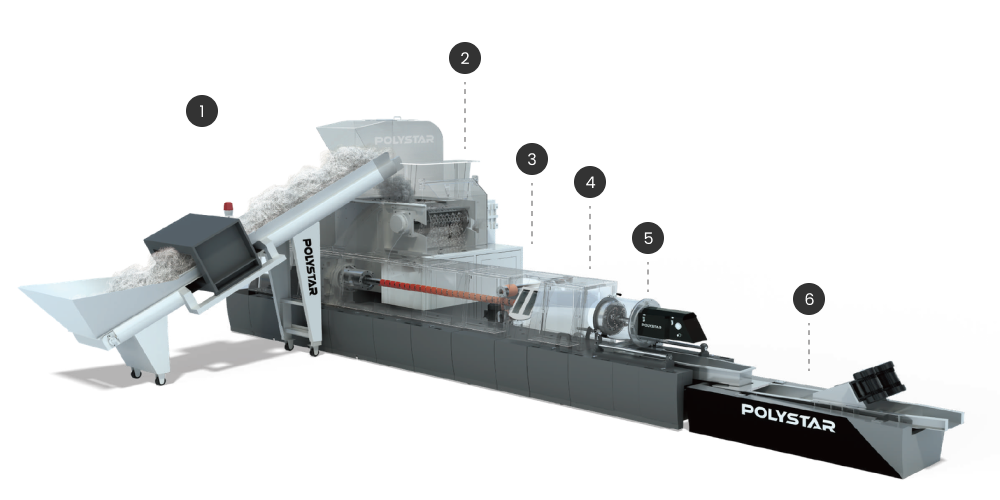

Recycling Process of Repro-One

-

1. Feeding System

Feeding of scraps (raffia, film, lumps) is simple by a conveyor. -

2. Shredding

Shredder integrated & Direct feeding to extruder: Powerful yet gentle shredder, efficient size reduction with minimal material degradation. Fast and stable feeding from the shredder into the extruder. -

3. Filtration

Screen change with dual channel system: For non-stop operation and prevents material from leaking. -

-

4. Degassing

Two-zone degassing (double-vented degasification): Able to process films with larger printed area and some water content. -

5. Pelletization

Hot die face pelletizer: Produces high-quality plastic pellets for reprocessing. -

Recycled Pellets

The plastic pellets can be put directly back into the production line such as blown film extrusion and pipe extrusion.

Plastic Shredding Recycling Machine

This recycling machine is ideal for PP raffia/PP non-woven manufacturers who process their rejected raffia waste (tapes, fabric, jumbo big bags, lumps) generated from in-house production. The recycled pellets can be put directly back into tape extrusion lines for immediate reprocessing. These plastic recycled pellets can be loaded in high percentages and still produce excellent fabric with good tensile strength and elongation.

This eliminates the need for pre-cutting/pre-shredding large-sized, thick, or bulky waste (including hard plastics), feeding the waste directly from the shredder into the extruder at a very fast and constant rate without overheating the material. This technology ensures continuous and uniform feeding to the extruder that produces high-quality recycled pellets.

Ideal for Both Raffia and Film Waste

1. For Different Shapes of Plastic Waste

2. Single Shaft Shredder Integration

3. Minimal Material Degradation

Repro-One Catalog

-

Raffia

Raffia -

Jumbo Bag

Jumbo Bag -

Woven Sack

Woven Sack

-

Bottles/ Hard Plastics

Bottles/ Hard Plastics -

PP Ropes

PP Ropes -

Plastic Lumps/ Bulks

Plastic Lumps/ Bulks

-

PP Woven Bag

PP Woven Bag -

PP Non-woven Bag

PP Non-woven Bag -

Film Roll/ Scraps

Film Roll/ Scraps