We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

PP Raffia/ Woven Recycling

PP woven materials, including bags and geotextiles, excel in bulk packaging, civil engineering, and flood control. They are commonly employed for shopping, industrial purposes, and as ground covers in gardening. These versatile materials play crucial roles in various industries and daily activities, thanks to their strength and durability. PP woven materials can be recycled to help reduce plastic waste.

How to Recycle PP Raffia / Woven Materials?

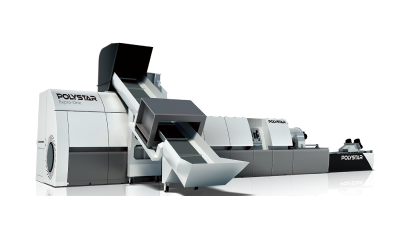

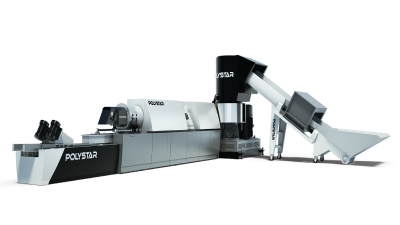

High Performance Recycling Machine

-

1. Minimal changes in MFI

Ensures high loading of recycled pellets in the tape extrusion process with excellent tensile strength and elongation. -

2. Superior degassing effect

Degassing with vacuum pump ensures a superior degassing effect providing excellent quality pellets from even heavily printed material.

-

3. Faster and more stable material feeding

The improved design of the shredder now works superbly with PP raffia scrap. The single shaft shredder allows efficient cutting of the material enabling a fast and stable feeding from the shredder directly into the extruder. -

4. Adding masterbatch and compounds

The additive feeder feature is very helpful in homogeneously blending the recycled polymer melt with color master batch or additive master batch to give the desired quality to the recycled pellets.