We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

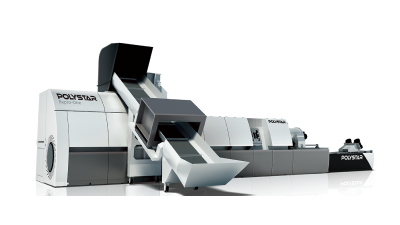

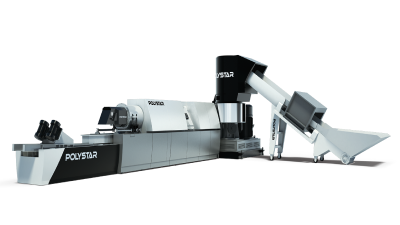

Non Woven Recycling

Non-woven PP is essential in the medical field for producing disposable gowns, masks, and hygiene products. It also finds its way into furniture upholstery, automotive components, construction materials, and geotextiles. Additionally, it plays a role in the production of home and garden items, mattress covers, packaging materials, insulation, and more. Its durability and eco-friendly properties make it a preferred choice in various industries.

How to Recycle Non-Woven PP Materials?