We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

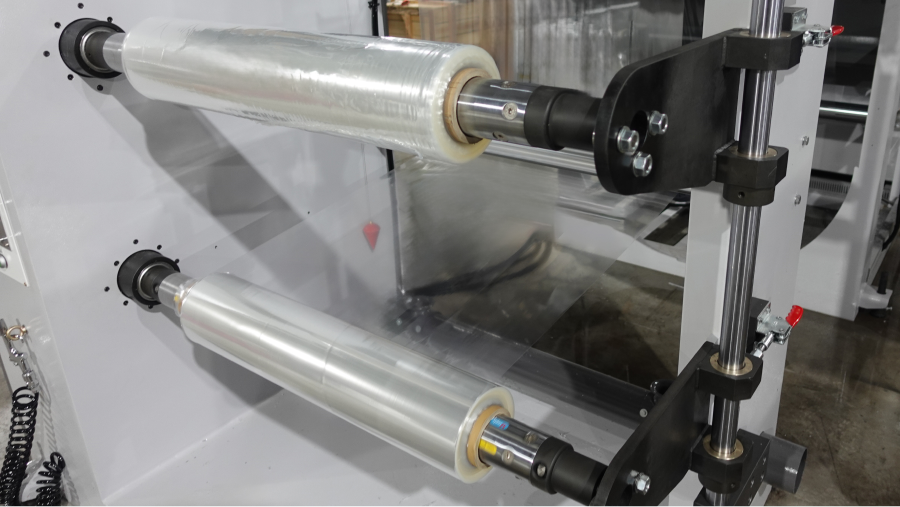

PP Blown Film Machine

Flexible Design for PP Plastic Film Production

POLYSTAR’s PP blown film machine is designed specially for producing PP (Polypropylene) film of high transparency and clarity. The downward extrusion machine produces high-quality PP film rolls suitable for the textile and garment industries, as well as in food packaging, stationery products, flower packaging, zipper bags, and other transparent packing bags. The water-cooling system ensures the transparency of the final film product.

Customized machine design: Screw sizes are available in 45mm, 55mm, 65mm, and 80mm for different output capacities and film width. The standard machine includes 10 sets of different-sized water rings for the flexible production of different-sized final film products. The special air ring design ensures the stability of the PP bubble during the production process.

Flexible add-ons and auxiliary equipment:

- Air/water chiller can be added to enhance the transparency of the PP film

- Rotary die head can be equipped to ensure the film roll surface is smooth and beautiful

- A double (back-to-back) winder can be equipped to produce a single-layered sheet

- Optional tension control for winder provides good tension film (in rolls), especially effective in food and garment packaging.

Blown Film Machines Catalog

-

Food packaging bag

Food packaging bag -

Anti-fog Freezer Bag

Anti-fog Freezer Bag -

Carrier Bag

Carrier Bag

-

Flat Film Rolls

Flat Film Rolls -

Bread Bags

Bread Bags -

Laundry Bags

Laundry Bags

-

Sauce Bags

Sauce Bags -

Bags for Clothes Packaging

Bags for Clothes Packaging