We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Laminated Film Recycling

In packaging, laminated films protect food, beverages, pharmaceuticals, and consumer goods from moisture, oxygen, grease, and other contaminants. They also make packaging stronger, more durable, and visually appealing.

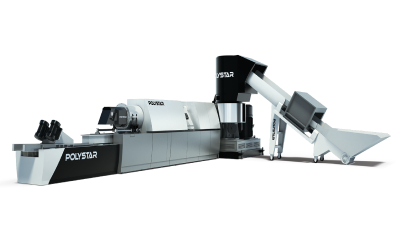

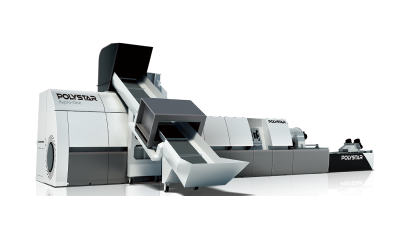

High-performance recycling machine for laminated film

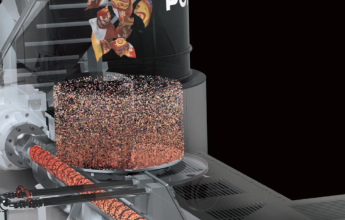

Specialized screw design

Our screw has been engineered to effectively process laminated, metallized, and fully printed film waste. This innovative design allows the screw to facilitate optimal mixing without causing degradation, ensuring a gentle processing experience, even for abrasive materials.

Easy pelletizing