We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

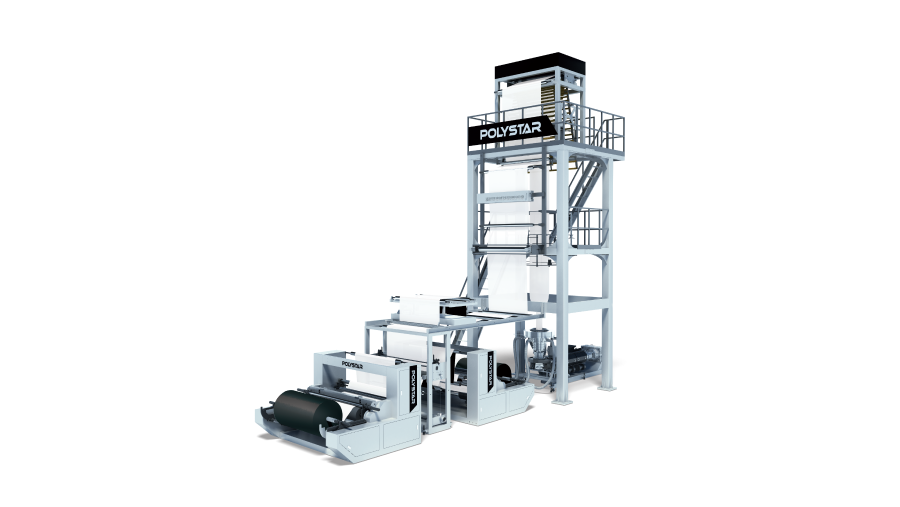

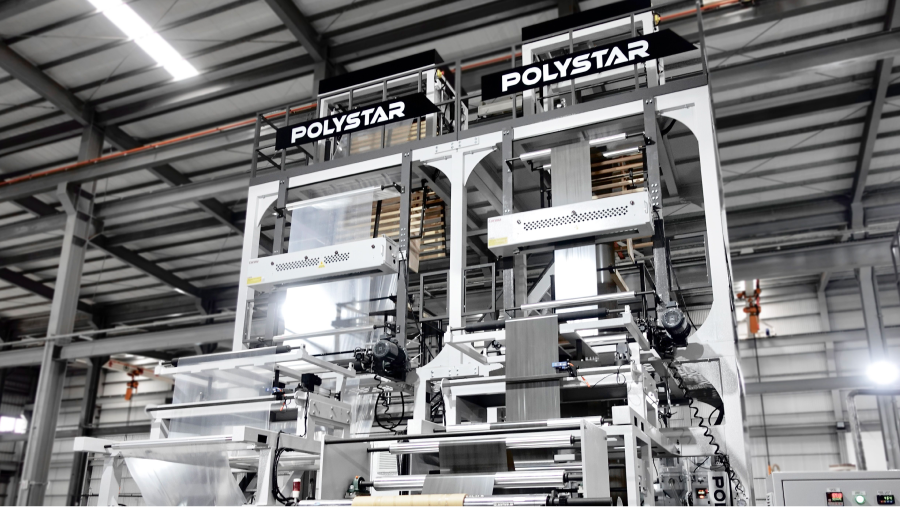

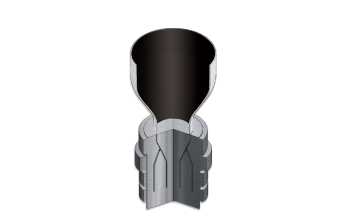

Two Layer AB Blown Film Machine

Productive. Flexibility.

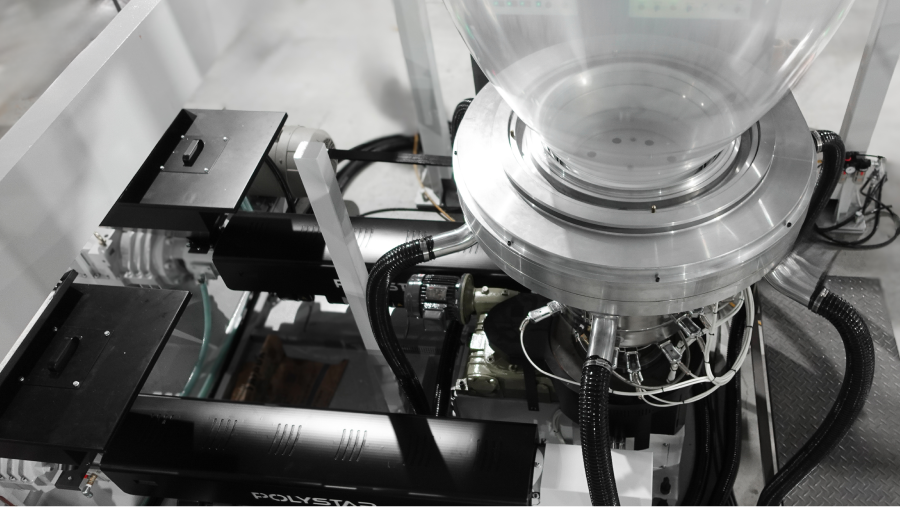

AB Two-layer blown film machines produce two-layer films by combining and co-extruding materials from two extruders through a die. The die-head design ensures good color separation on each layer. This machine is used to produce a wide variety of films, including agricultural films, food packaging films, industrial packaging films, consumer packaging films, and medical and pharmaceutical packaging films.

Advantages of Two Layer AB Blown Film Machine

More Durable

Two Sides with Different Colors

Blown Film Machines Catalog

-

Mulch Film

Mulch Film -

Agricultural Film

Agricultural Film -

Packaging Film

Packaging Film