We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

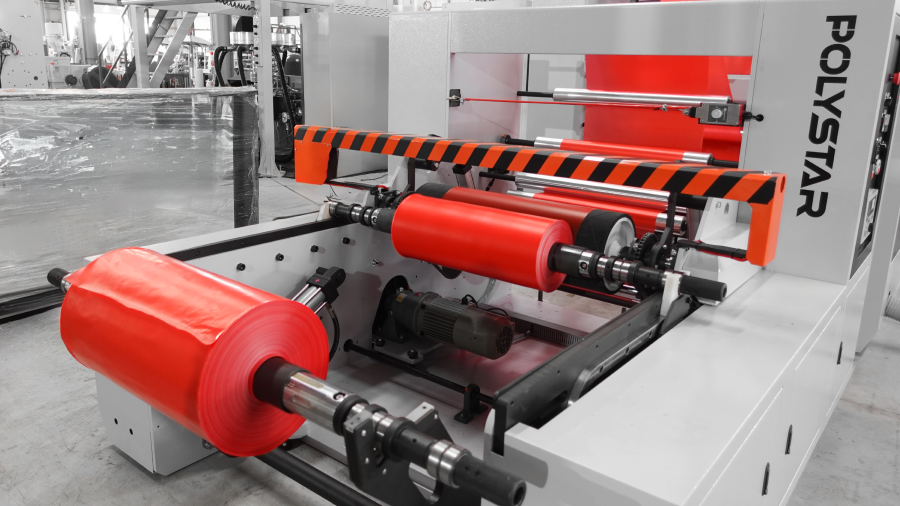

Simple in Design. Productive. Flexible

Monolayer Blown Film Extruder

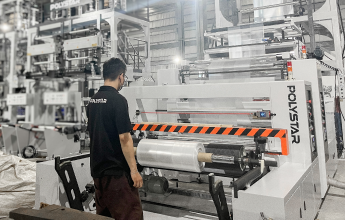

The standard blown film machine, Star-X, provides a good solution for a single-layer (monolayer) of HDPE, LDPE, and LLDPE for general packaging, at a high quality and speed. Suitable for general packaging products such as T-shirt bags, supermarket bags, flat bags, and many others.

The film width is available from 800mm to 2300mm, which can be customized based on customers’ requirements. The specially designed extruder has a good ability for melting and mixing the material with masterbatch and additives, allowing producers to use a higher percentage of recycled material and CaCO3. High-precision die head and cooling air ring provide good film thickness control and resistance.

Advantages of Standard Blown Film Machine

Flexibility

Star-X, the standard blown film machine, provides the advantages of good melting and mixing of HDPE, LDPE, LLDPE, CaCo3, recycled materials with masterbatch, additives, and recycled plastic.

Cost-Effective

Easy-Operation

Blown Film Machines Catalog

-

T-shirt bag

-

Shopping bag

-

Garbage bag

-

Bottom-Sealed Bag

-

Bag-on-roll

-

Shrink film