We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Post Consumer Recycling

PCR materials are typically collected through various recycling programs and must be properly washed and dried before being processed into pellets on pelletizing lines. Once recycled, the plastic pellets are used to manufacture new products based on their physical properties.

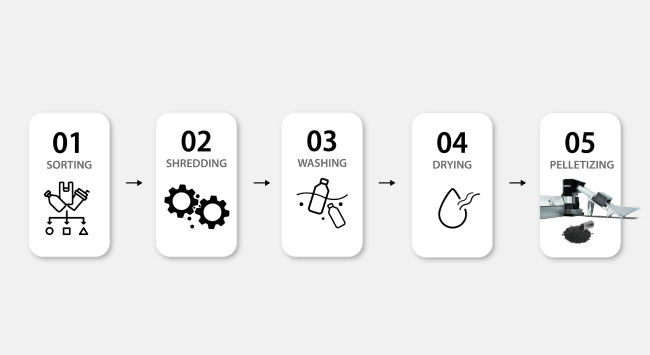

How to Recycle Post-Consumer Plastic Waste?

To recycle post-consumer plastic, these materials must first go through previous sorting, shredding, washing, and drying lines. Once the materials have been properly cleaned they can be placed into pelletizing machines to transform the plastic waste into pellets.

For many producers, recycling postconsumer plastics has become an ideal way to increase the amount of recycled materials used in their production.