We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

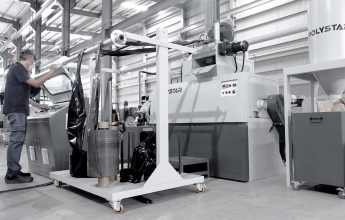

Small Plastic Recycling Machine

Small Plastic Recycling Machine

Recycling Processes of Repro-Air

-

1. Feeding

Manual FeedingFeeding by nip roller -

2. Extrusion

Melting the plastic waste and transfer to the pelletizing system. -

3. Pelletizing System

Hot die face pelletizer :

Produces high-quality plastic pellets for reprocessing

Mini Plastic Recycling Machine

No Water Need in the Recycling Process

Effectively Pelletizing

Compact Design for Space-saving

-

Film-on-rolls

Film-on-rolls -

T-shirt Bag Cut-offs

T-shirt Bag Cut-offs -

Leno Bags

Leno Bags

-

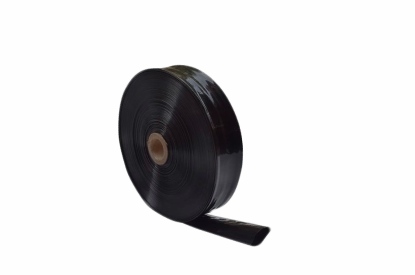

Soft Irrigation Pipe

Soft Irrigation Pipe -

Stretch Film

Stretch Film -

Shrink Film

Shrink Film