We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Blown Film Extrusion Manufacturer

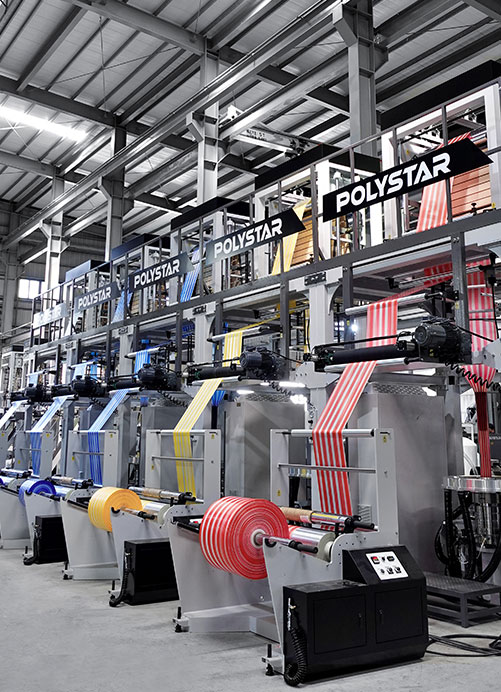

Know-How as Blown Film Extrusion Machine Manufacturer

Besides having knowledge of plastic film recycling, another plus of the company is producing blown film extrusion machines, as one of the reliable blown film extrusion machine manufacturers in Taiwan. Most of the time, POLYSTAR supplies both plastic film recycling machines and blown film extrusion machines as a package to many of its customers.

This gives POLYSTAR the leverage to cooperate even more closely with its clients and understand their requirement better as their blown film extruder supplier. From regular customer feedback and information on new market trends, POLYSTAR is able to re-engineer its machines to be more stable, efficient, and productive to remain competitive in the market.

For film producers, POLYSTAR has often offered a package of A-B-A blown film extrusion machines with its plastic recycling machine, giving its clients the advantage to produce cost effective 3-layer film with 75% Caco3 or recycled materials in the center layer.

What are the Advantages of ABA Blown Film Extrusion Machines?

The cost of virgin (raw) material (HDPE/ LDPE) continues to go up every year, and therefore many packaging film producers equipped with co-extrusion blown film extrusion machines have started to make 3 layer (ABA) films to reduce cost, replacing the traditional single and two layer blown film extrusion machines to stay competitive in the market.

The main advantage of the ABA blown film extrusion machine is that it can use up to 75% recycled material with CaCo3 (Calcium Carbonate) in the middle layer. This significantly reduces the cost of raw material while maintaining the film quality at a high level.

Other advantages of the ABA 3 layer blown film extrusion machine are:

- Reduces the use of white masterbatch, antistatic and other types of additives to reduce cost.

- Produces film with higher resistance (strength).

- More economic than the typical 3-layer ABC blown film extrusion machines that runs with 3 extruders. The ABA blown film extrusion machine is equipped with two extruders.

POLYSTAR Brand Story towards Renowned Blown Film Extruder Manufacturer

With over three decades of manufacturing blown film extrusion machines as an OEM manufacturer, POLYSTAR Taiwan has produced over three thousand sets of blown film extrusion machines since the 1990s.That makes POLYSTAR one of the most experienced blown film extruder manufacturers in the industry.

Due to the lack of brand name and visibility, its sales network was limited, exporting mainly to Europe. The situation has, however, changed radically since 2010 when POLYSTAR converted itself into a brand that manufactures blown film extrusion lines.

"I believe what differentiates us from other Taiwanese blown film extrusion manufacturer is our service. We give surety that all of our representatives are service-oriented with a skilled engineering team to customers who have purchased blown film extrusion machines from POLYSTAR."

A Variety of Blown Film Extrusion Machines and Parts Offered by POLYSTAR

POLYSTAR produces a wide range of blown film extrusion machines and related components for all types of customer requirements. You can contact POLYSTAR to have more info and quotation about its blown film extruders and their components.

Blown Film Extruders:

- One-layer Blown Film Extrusion Machine

- Twin-Head Blown Film Extrusion Machine (One Extruder, Two Die Heads)

- Compact-type Blown Film Extrusion Machine

- Shrink Film Blown Film Extrusion Machine

- Co-Extrusion Blown Film Extrusion Machine

- AB Double-Layer Blown Film Extrusion Machine

- ABA Three-Layer Blown Film Extrusion Machine

- ABC Three-Layer Blown Film Extrusion Machine

- Two-Color Blown Film Extrusion Machine

Timely Service is the Key for After Sales Services

Focal Markets for the Blown Film Extrusion Manufacturer

POLYSTAR has exported its various machines to more than 110 countries worldwide, primarily in Eastern Europe, Southeast Asia, Middle East, Africa, North America and South America.

Besides, the local agents web of the company is also developed worldwide. This is beneficial for the customers to receive even quick response. As well as, they can also assist for showing a running POLYSTAR machines in a customer’s factory in the local market of the buyers.

POLYSTAR provides high quality equipment at reasonable prices for companies of all sizes in the packaging industry. Over the past years, POLYSTAR justifiably proud to grow its sales year over year, and has successfully transformed itself into a brand name of blown film extrusion manufacturing.

POLYSTAR at Global Trade Shows

As an experienced blown film extruder and plastic recycling machine manufacturer, POLYSTAR has exhibited in many major plastics exhibitions in the world. Those are included K show in Germany, The Plastics Recycling World Expo in US, CHINAPLAS, Taipei Plas, Plastimagen in Mexico, Plast Eurasia in Turkey, and many.

- Visit our exhibition page and meet POLYSTAR at the exhibition in your local market.

-

Make an Inquiry!

-

Blown Film Machines

-

YouTube Channel

__23K30Ohjte.jpg)