We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Recycled Plastic Pellets from PP Raffia and Woven Production – Tips to Reuse them Better

Which recycled plastic pellets should go back to PP tape extrusion line?

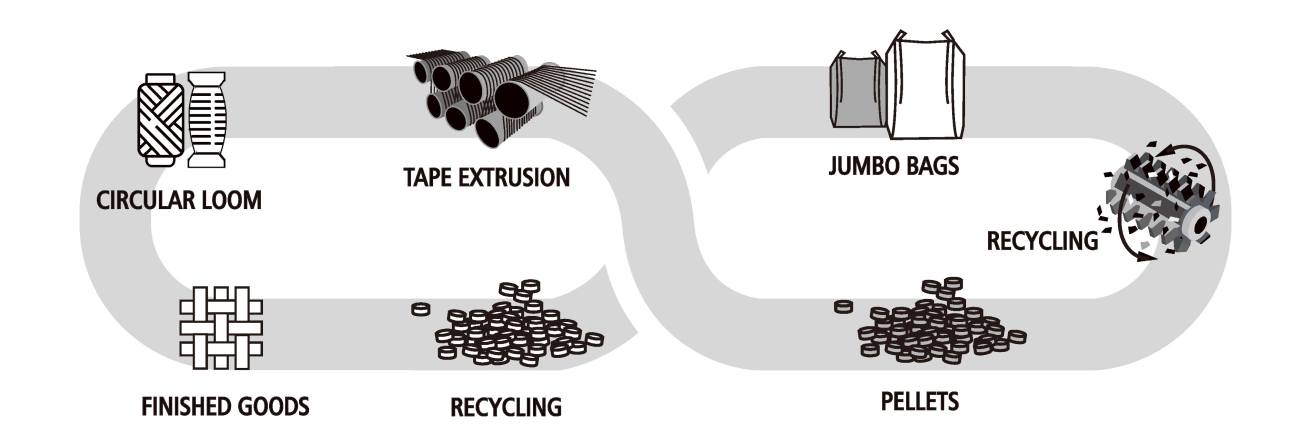

On average, a 5-10% production waste is generated during the PP woven bag-making process at different stages of the production: extruder start-up lumps, waste due to blockage in extruder die head, tape winding, circular loom (weaving defects), coating/lamination stage, pp woven/FIBC bag conversion and printing. Here we have some tips to reuse recycled plastic pellets from PP raffia and woven production better.

Recycled pellets (granules) from different types of post-industrial waste are used for producing different products, we will share the most common ones below:

1. PP raffia (woven fabric), yarn waste, broken tapes and endless tapes

The post-industrial waste generated during the tape extrusion (tape stretching) and circular looming process has the highest reusability back to tape extrusion lines, in many cases up to 100%.

The reusability level might vary depending on the formula of the raffia waste itself (such as material formulation and the percentage of calcium carbonate it contains), but raffia producers should not find any problem in reusing the recycled pellets back to their tape extrusion lines.

2. Printed PP woven / laminated bags

Some raffia producers are able to reuse the pellets from the printed bags in tape extrusion lines but in a relatively small percentage compared to the recycled pellets from non-printed raffia.

In addition, the output can be slightly affected as the production line speed has to be reduced (in order to prevent the tapes from breaking during production). This grade of recycled pellets is normally used for reduced-tenacity applications.

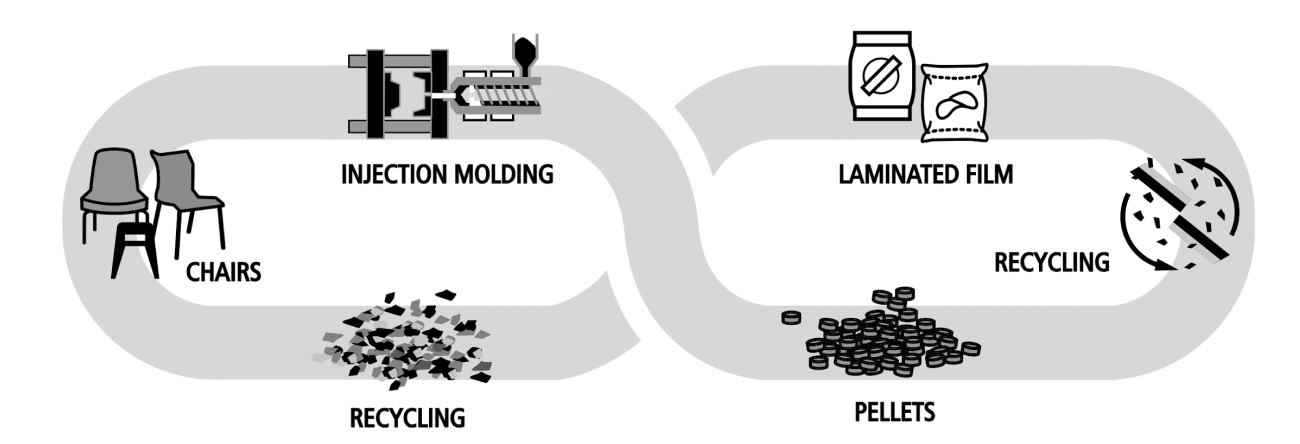

Hence, apart for their reusability in PP raffia production, recycled pellets from heavily printed PP woven bags such as AD*Star bags, cement bags, fertilizer bags, sugar and salt bags can easily be used again in injection molding applications as well as for making PP ropes, PP straps and PP thread.

Similar to the recycled pellets from post-consumer (washed) PP jumbo bags as well as laminated PP+PET film and PP non-woven scraps of mixed colors, a majority of the recycled pellets can be reused in injection molding applications.

4 Tips to increase the reusability of the recycled pellets (during the recycling process)

In order to maximize the reusability back to the tape extrusion lines, the processing temperature throughout the entire recycling process is very important, especially for post-industrial PP raffia and woven waste.

The use of an agglomerator should be avoided in order to prevent overheating and degrading the high-value material waste. Instead, a single-shaft shredder integrated recycling machine is recommended.

The gentle size reduction and low processing temperature in the shredder are the ideal solutions to minimize changes in material properties.

2. Better drying of pellet surface

3. Better degassing for heavily-printed woven bags

Good degassing during the extrusion recycling process is another crucial factor in improving the reusability of the recycled pellets.

4. Adding modifiers during the recycling process

The usage of additives can affect the reusability of recycled pellets back in production. Performance-enhancing modifiers or additives can be added to recycled plastic extruders to improve the properties of the recycled pellets to improve the properties of the recycled pellets.

The usage of modifiers during the recycling process or directly in the tape line along with recycled pellets ensures easy melt flow-ability and better dispersion, higher elongation, reduced torque, and an increase in throughput. The additives we use during additives we use to add to the recycled plastic extruder are performance-enhancing modifiers made from elastomers, anti-oxidants, special lubricants, and additives.

Summary - A quick comparison chart

Recommended for reprocessing in tape extrusion lines:

| Type of Production Waste |

Reuse in Tape Extrusion |

Keys to Increase Reusability |

|---|---|---|

| PP Raffia | Up to 100% |

Low processing temperature in the recycled plastic extruder to prevent degradation and retain material strength. |

| Endless tape | Up to 100% | |

| Yarn waste | Up to 100% | |

| Printed or laminated bags | Smaller percentage (around 10~15%). For tapes with reduced strength running at lower line speed |

Good degassing, Good filtration, Good pellets surface drying |

| Type of Production waste | Reuse in Injection Molding | Keys to Increase Reusability |

|---|---|---|

| Coated fabric |

PP chairs and furniture |

Good degassing, |

| Woven bag making (Conversion waste) |

||

| Heavily printed fabric |

About the Author

Jack Lin

Sales ManagerJack has visited and spoken to hundreds of POLYSTAR machine users around the world over the last 10 years. Having collected practical information on customer feedback and user experiences, he enjoys sharing the advantages and disadvantages of using different types of machines with others, especially coming from the customers' perspectives.