We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

How to Use Recycled Plastic Pellets in the Production Process ?

Plastic pellets made from post-consumer waste are small granulates, used in production processes such as in Blown Film Machines, Injection Machines, Plastic Molding Machines, and other machines that produce plastic films, bottles, containers, bags, and more.

These small pieces of material are the most important in the process of plastic products. Not only because they are the principal material but also because they give the quality of the final product.

The industry of plastic is quite big but without virgin materials, the industry will collapse. Therefore, it is important to take care of this situation. Around the world, there is a big consumption of plastic, and most of this plastic is necessary for health.

Why is it important to recycle plastic products?

We need to be aware of whether the products that we consume can be recycled or not. If you know the material of your products you will know if they can be recycled and used once again in the production line.

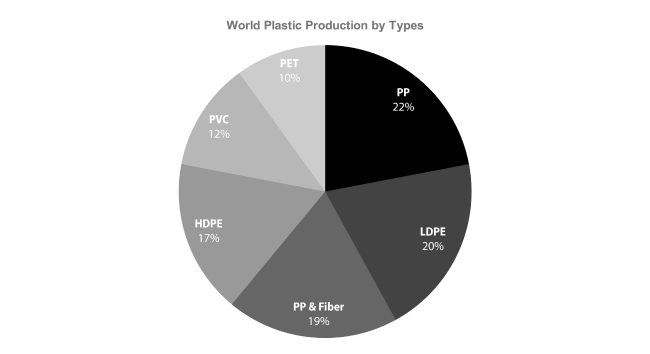

This time we will emphasize the materials that can be recycled like HDPE, LDPE, LLDPE, and PP.

We focus on these materials because they have higher consumption compared to others. (See the graphic)

How to recycle post-consumer plastic waste?

Post-consumer waste becomes dirty and humid. Therefore, the recycling process will start with a washing line. The washing line will have three steps:

-

Crushing

The plastic waste will be put into a shredder to reduce its size.

-

Washing

The washing line will remove the dirt and grease that the waste contains.

-

Drying

After going through the washing line it is necessary to reduce the humidity of the waste to a level of 3%-5%. In this way can be recycled in the plastic recycling machine

Two-Stage Recycling machine by POLYSTAR:

Repro-Flex Plus model comes with a cutter-compactor. The cutter-integrated pelletizing system eliminates the necessity of pre-warming the material before extrusion. After cutting and compacting the waste will be fed directly into the extruder with a centrifugal force.

This recycling machine can reprocess PE and PP films, multi-layered films, stretch films, EPE foam, pre-washed film flakes, and non-printed and highly surface-printed films (up to 95%). This is possible thanks to the repositioning of the filter and the third degasification in the venting area between the first and second extruder.

- Read More: Single-stage vs. Two-stage Recycling Machine

- Watch Video: Two-stage recycling machine -Repro-Flex Plus

Two-stage plastic recycling machine

Recycled pellets for production

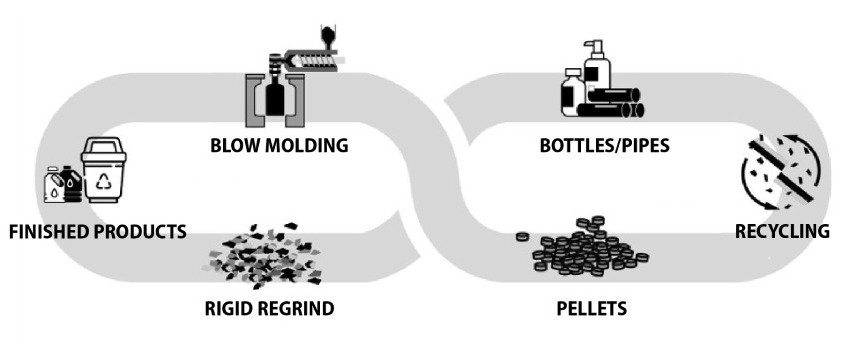

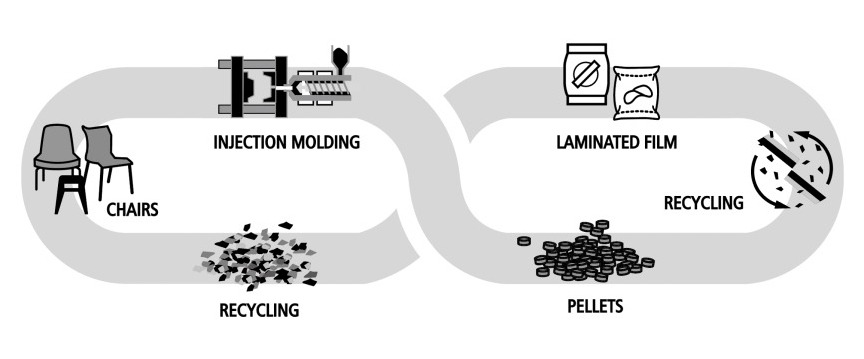

Each material has different properties, for this reason, it is important to know what you can do with them after the production of recycling pellets. Unlike the in-house recycled pellets, the post-consumer recycled pellets can’t be used to produce the same product as before.

For example, if you recycled in-house film rolls you can use the recycled pellets from these films into film rolls again. But in the case of post-consumer waste recycled pellets, there are different uses.

These are some products that you can make with recycled pellets from post-consumer waste:

R-HDPE:

- Industrial bags

- Detergent bottles

- Traffic cones

- Trash cans

- Flowerpots

- Others

R-LDPE:

- Garbage bags

- Thermoplastics

- Containers

- Agricultural films

- Construction films

R-PP:

- Battery boxes

- Broom fibers

- Plastic chairs

- Textiles

- Trays

About the Author

Maria Lopez

Marketing ManagerMaria Lopez is a content marketer at POLYSTAR. She authors in-depth guides that provide solutions to Plastic Producers. Not only to select your machine but also to keep you updated with the new trends.