We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

How to Recycle Rigid Plastics?

Today, environmental issues are more important than ever, and people are becoming more conscious of their surroundings. Being able to live a more sustainable life is something that can help improve our lives and contribute to the planet. Plastic recycling is a great way to help the environment. In this article we will focus on how to recycle rigid plastics.

Due to the increasing number of producers and people talking about the importance of recycling, we at POLYSTAR provide a variety of flexible and cost-effective plastic recycling machines around the world. We aim to help our customers understand the importance of the process and provide them with the necessary machines to make an easy and stable operation.

What are rigid plastics?

Rigid plastics, often known as hard plastics, are used in the manufacturing industry and everyday life. In comparison to flexible packaging (such as films and bags), rigid plastics provide better protection for the goods. Plastic chairs, toy parts, baskets, trash cans, pipes, bottles, bottle caps, and other items are examples of this.

( Rigid plastic )

What is the recycling process for rigid plastics?

The majority of post-industrial and post-consumer trash ended up in landfills. As a result, they lose their ability to be recycled and enter the circular economic process.

Rigid plastic solutions are now widely popular all over the world. Here are two simple ways to get started with the circular economy:

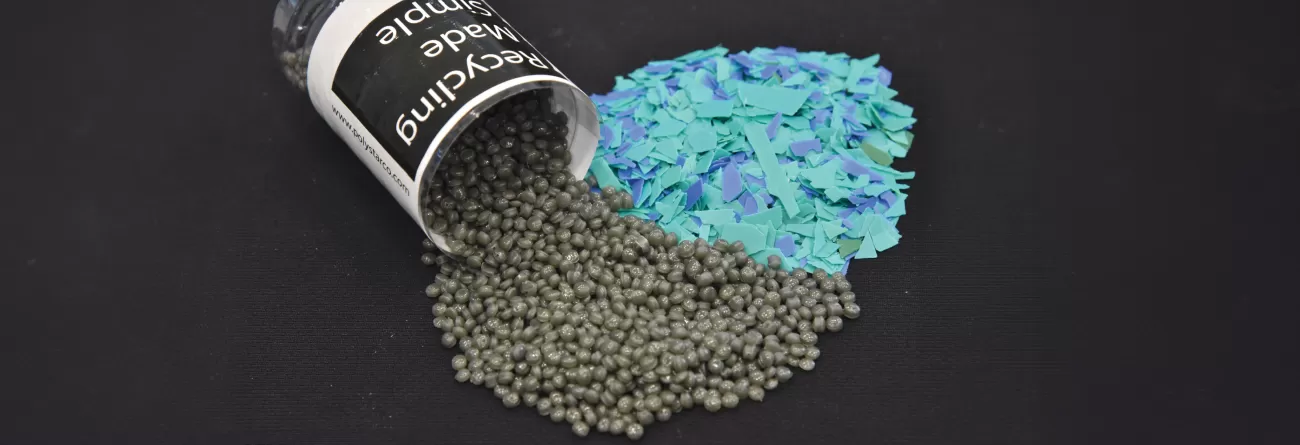

1. From hard plastics to rigid regrind

2. From rigid regrind to recycled pellets

Hard plastic regrind is fed straight into the hopper in Repro-Direct, eliminating the requirement for pre-heating before extrusion. This system makes the process easier and faster for these highly abrasive materials throughout the whole pelletizing machine. Providing you with high-quality pellets for your production lines.* If the customer requests it, a belt conveyor can be added in exchange for the automatic screw feeder.

( PP regrind pellets )

Recycling rigid plastics from the post-industrial and post-consumer sectors is a better solution; you will increase your profitability and POLYSTAR will guide you in completing the circular economy process in your business.

About the Author

Maria Lopez

Marketing ManagerMaria Lopez is a content marketer at POLYSTAR. She authors in-depth guides that provide solutions to Plastic Producers. Not only to select your machine but also to keep you updated with the new trends.