We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Is Shrink Wrap Recyclable? Recycling Methods Explained

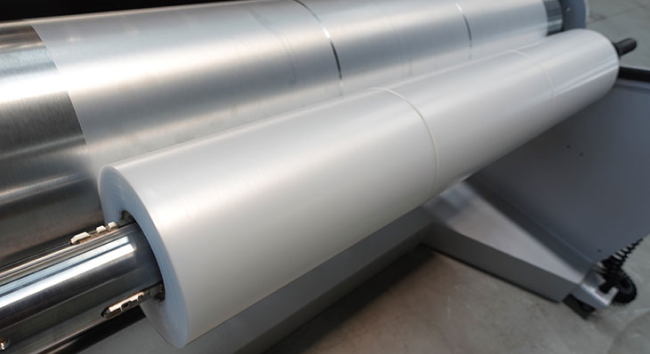

Shrink films are widely used for packaging applications in many industries because of their ease of use and superior wrapping properties. Such widespread usage brings with it the necessity of recycling shrink films. When Shrink films are recycled, it is possible to reuse the valuable plastic material they contain in production. In this article, we will mostly focus on the recycling of PE (Polyethylene) type shrink films.

What is PE Shrink Film?

4 benefits of PE Shrink film/wrap:

- 100% recyclable

- High durability & high flexibility for packaging

- Printable – allows to have high-quality graphic designs on it

- Cost savvy – cheaper alternative for corrugated boxes

What are the PE Shrink Film Applications?

Because of the ability to be easily blended with various types of polymers and additives, PE shrink films have a wider range of applications. For these reasons, we see them intensively used in printed and unprinted wrapping and packaging applications for logistics, foods, furniture, stationery, white goods, water bottles, boat wrapping, and hand tools. Moreover, strong wrapping ability, makes PE shrink film packaging a better alternative for corrugated trays especially for water bottle packaging, heavy tools packaging, and hand tools packaging.

Ideal Machine for Recycling PE Shrink Wrap Film

Advantages of Repro-Flex plastic pelletizer:

- A built-in cutter compactor ensures the shrink films are cut and fed directly and steadily into the recycling extruder.

- Automatic die face pelletizing system to obtain uniform and homogeneous recycled shrink film pellets

- Starter-friendly – Simple design and automation with smart recycling systems allow operators to learn to run plastic pelletizers in a short time

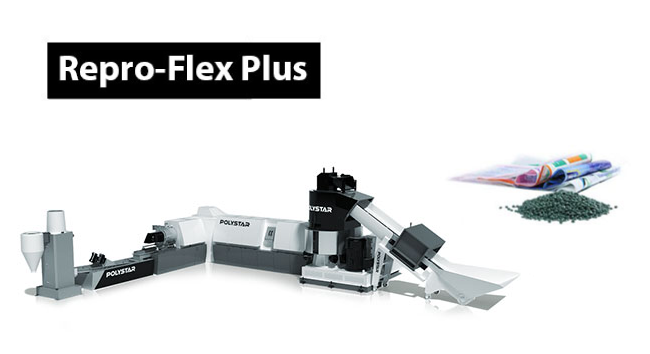

Pelletizer for Recycling Post-consumer and Printed PE Shrink Wrap Film

Advantages of Repro-Flex Plus plastic pelletizer:

- Stable two-stage recycling process for post-consumer and heavily printed PE shrink films through automation.

- Three Degassing & two filtration units to remove the extra moisture and ink from the post-consumer materials.

- Obtaining high-quality plastic pellets from post-consumer and heavily printed PE shrink films.

What are Recycled PE Shrink Wrap Pellets Used for?

Conclusion

About the Author

Resul Gökpınar

International SalesResul creates up-to-date content based on his experience, gained by solving customers' problems in Turkiye and the EMEA market.