We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

How to Obtain Excellent Quality Plastic Film? – For Laminated Packaging

Laminated film is ideal for packaging food like coffee, snacks, cookies, nuts (peanuts, pistachio, almonds), others. The reason is that they protect against humidity, oxygen, aromas, fats, and light. All of these factors decompose or reduce the lifetime of the packaged product. Therefore, the protective barrier is the most critical part of the laminated film, which is made of PE (LDPE), BOPP, PET, and others.

Design and Simplicity

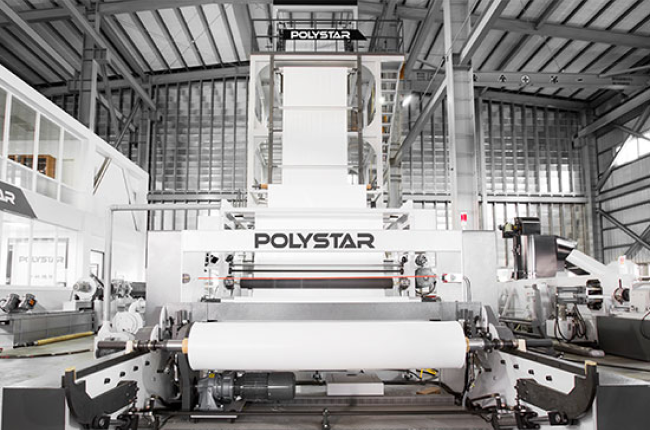

Co-Extrusion Blown Film Machines are fundamental to the lamination process. For this reason, POLYSTAR designs machines to guarantee the specific properties of the film rolls used in laminated films.

The following specifications are found on POLYSTAR Blown Film Machines Extrusion lines which enhance the film quality:

- Special screw design: adapting to customers’ requirements, POLYSTAR’s team of designers and engineers improved the functionality of the screw. The design maximizes the mixing of the materials, giving you a homogeneous film from the beginning to the end of production.

- Taiwanese Air Ring and Die head: the quality of the design, control, and capacity that they provide is outstanding compared to conventional machines. As a result, there is an immediate improvement in production and thickness control.

- Stabilizer (round shape): a simple design that protects the bubble during the production process by keeping it from being damaged or marked.

- Line speed control: Improved winder technology for controlling the speed between different stages.

All these characteristics make producing high-quality plastic film rolls possible because they give customers a greater level of control over the thickness of the plastic film.

Compared to conventional machines that only have one or two quality components, POLYSTAR machines feature excellent quality and advanced technology for the production of plastic films.

The final product from POLYSTAR machines will be of high quality and will meet all the requirements for laminated films, while traditional machines will have lower quality film rolls that cannot be used for laminated films.

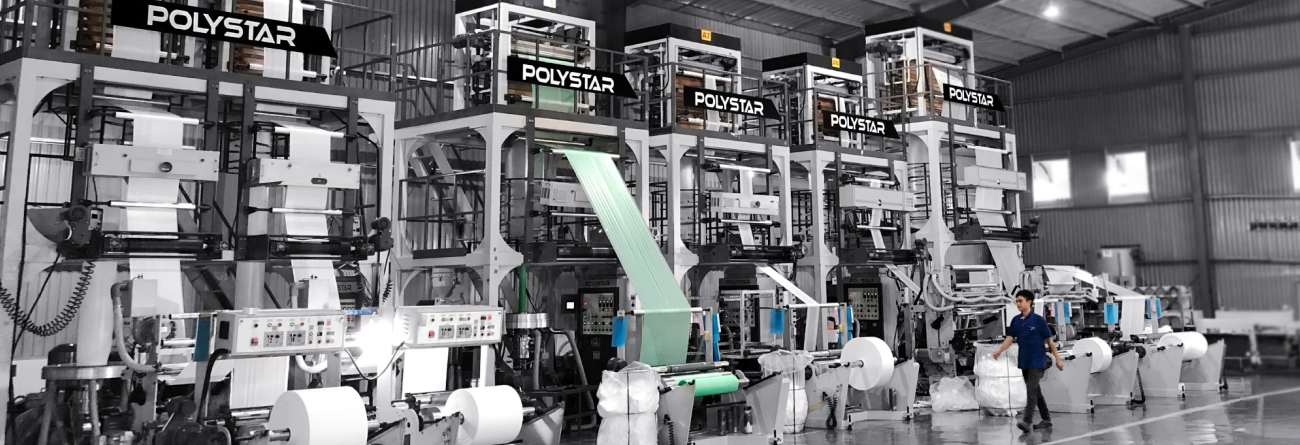

POLYSTAR Blown Film Machines (Co-Extrusion)

If you are a laminated film producer, POLYSTAR recommends:|

Bi-X 55-55-1500 AB Co-extrusion

|

Tri-X 55-65-55-1700 ABC Co-extrusion

|

|

| Number of extruders | 2 | 3 |

| Layers | 2 | 3 |

| * Production capacity | 90 ~ 160 kg/hr | 180 ~ 300 kg/hr |

| * Maximum width | 1600 mm | 2400 mm |

You can use either model to produce plastic films that are intended to be used for laminated films. The film quality produced by these machines is impeccable.POLYSTAR also offers the possibility to customize the machines according to your needs.

In addition to the high-quality film that Blown Film Machines produces, customers are also satisfied with the cost-saving benefits that they gain from these machines.

POLYSTAR’s co-extrusion lines operate around the world because of the excellent components made by POLYSTAR.

About the Author

Maria Lopez

Marketing ManagerMaria Lopez is a content marketer at POLYSTAR. She authors in-depth guides that provide solutions to Plastic Producers. Not only to select your machine but also to keep you updated with the new trends.