We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

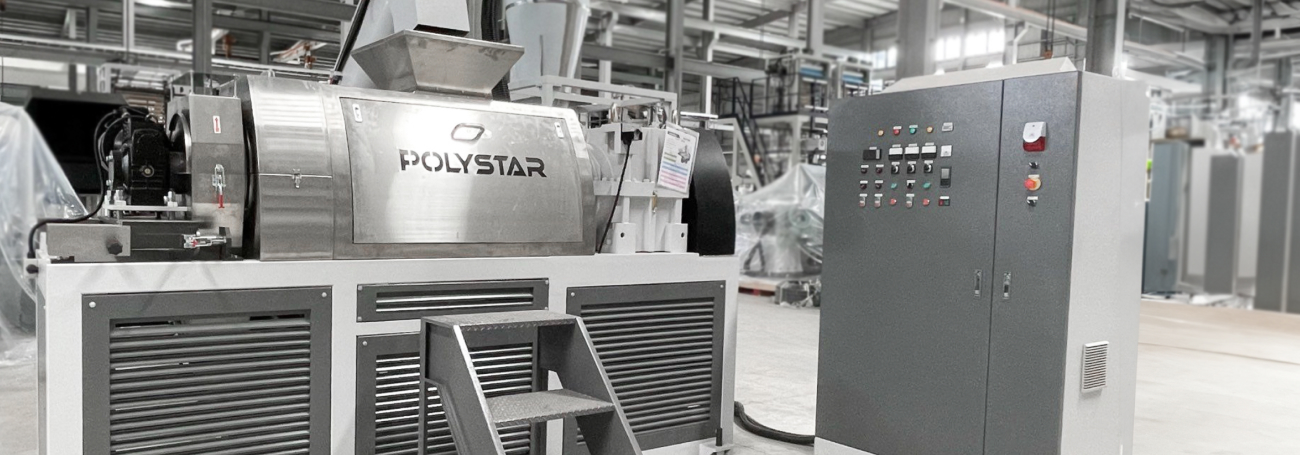

How does Squeezer Dryer Improve Post-consumer Plastic Film Recycling?

In post-consumer plastic recycling, pre-washed film waste coming directly from the washing line contains a very high percentage of moisture that is difficult to reduce using traditional drying machines.

Even after the drying process, the excessive water that remains in the light-weight plastic film flakes results in inconsistent feeding and low output in the plastic extruders.

One of the better solutions to improve the drying process is to use the plastic squeezer dryer.

It offers a fast and efficient way to reduce moisture levels from 40% down to only 2-5%, which better prepares the plastic material for the extrusion-pelletizing process that follows.

Process and main functions

First, the specially designed short screw “squeezes” and presses out the remaining moisture out of the washed plastic materials.

Second, it converts the lightweight plastic film flakes into a heavier, granule-shaped form, which then can be transported to the plastic extruder more easily and consistently.

Key benefit

The plastic squeezer dryer is designed to fit between the washing line and plastic recycling extruder to improve the overall recycling process, which includes:

- Higher output capacity

- Higher efficiency

- Better pellets quality

Best when used with a cutter-compactor plastic recycling extruder

According to many of our customers’ feedback, the plastic squeezer dryer works best together with the cutter-compactor integrated recycling extruder, as the compactor further stabilizes the feeding into the plastic recycling machine.

About the Author

Jack Lin

Sales ManagerJack has visited and spoken to hundreds of POLYSTAR machine users around the world over the last 10 years. Having collected practical information on customer feedback and user experiences, he enjoys sharing the advantages and disadvantages of using different types of machines with others, especially coming from the customers' perspectives.