We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Common Uses for 3-Layer Blown Film Machines in the Plastic Industry

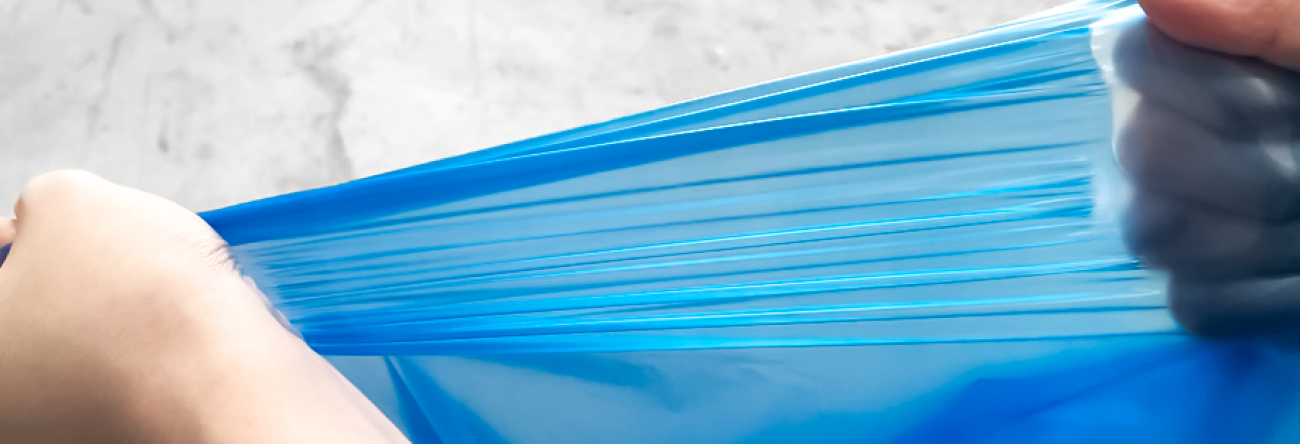

3-layer or multilayer plastic films are highly demanded in the packaging industry due to their superior tear and heat resistance, as well as excellent moisture and oxygen barrier properties.

For producing 3-layer plastic films, ABA and ABC co-extrusion machines are the options to go, with the processed materials including HDPE, LDPE, LLDPE, recycled, and biodegradable materials. However, although both of them produce 3-layer films, their structures and purposes vary, including the extruder numbers, die head design, and the final product applications.

How do ABA and ABC Blown Film Extruders Work?

-

ABA Co-extrusion Machine

- 2 extruders

- 3 flow channels in the die head

The term ABA refers to a film structure that can use two types of materials/ colors/ properties. A-A layer is the outer and inner layers composed of the same material, while the B layer represents the middle layer.

One of the benefits of ABA extrusion machines is to reduce manufacturing costs. The specially designed screws and the structure of the die head allow producers to apply a higher percentage of sustainable materials in the middle layer, including recycled material, biodegradable material, and CaCO3. By doing so, virgin resins can be reserved for the outer layers.

-

ABC Co-extrusion Machine

- 3 extruders

- 3 flow channels in the die head

ABC extrusion machines, on the other hand, consists of 3 extruders. Each extruder can be used to process a different materials/ colors/ properties, allowing for customization of the layers based on the specific product requirements.

One of the advantages of the ABC extrusion machine is its flexibility in producing 3-colored plastic films. By changing the die head, the extruder can produce a multicolored film with up to three different colors. This feature provides producers with more options to create unique and visually appealing products.

Differences Between ABA and ABC Film Applications

ABA films are widely used for producing a variety of bags, including T-shirt bags, garbage bags, and supermarket bags. These films are preferred for packaging applications that require higher strength and durability.

On the other hand, 3-layered ABC films are for even more demanding applications that require superior strength, durability, and barrier properties such as greenhouse films, agricultural mulches, construction films, and medical packaging. The production of 3-colored films can be T-shirt bags and shopping bags which are more visually appealing.

( ABC co-extrusion film applications: agricultural mulches, greenhouse film, 3-colored T-shirt bag )

Conclusion

The specially designed screws allow both machines to process HDPE, LDPE as well as LLDPE and well mix them with recycled and biodegradable materials.

With lower virgin materials used, the ABA co-extrusion machine reduces manufacturing costs and makes the final products more eco-friendly. It is also more cost-effective to produce 3-layer films with only two extruders compared to ABC.

ABC co-extrusion machines can produce films suitable for a wide range of applications, from everyday packaging to specialized industries that require high-performance materials, offering more flexibility and customization options for producing unique products.

Comparison between two types of co-extrusion machines |

||

| Machine model | ABA Co-extrusion Machine | ABC Co-extrusion Machine |

| Extruder number | 2 | 3 |

| Film layer | 3 | 3 (1 layer for 3 colored films) |

| Film thickness | 0.01mm~0.1mm | 0.1mm~0.2mm |

| Processed materials |

HDPE, LDPE, LLDPE, recycled material, biodegradable materials, CaCO3, masterbatches, and additives | |

| Applications |

|

|

| Advantages |

|

|

About the Author

Janine Cheng

Marketing AssistantJanine creates engaging content for POLYSTAR’s social media presence, including keeping social media channels updated and brand-focused and seeking ways of connecting with plastic producers and recyclers.