We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Co-extrusion AB and ABA Blown Film Machine - A Simple Comparison

Both AB and ABA co-extrusion blown film machines consist of 2 extruders, the main difference between the two is the design of the material flow channels in the die head.

What is AB co-extrusion machine?

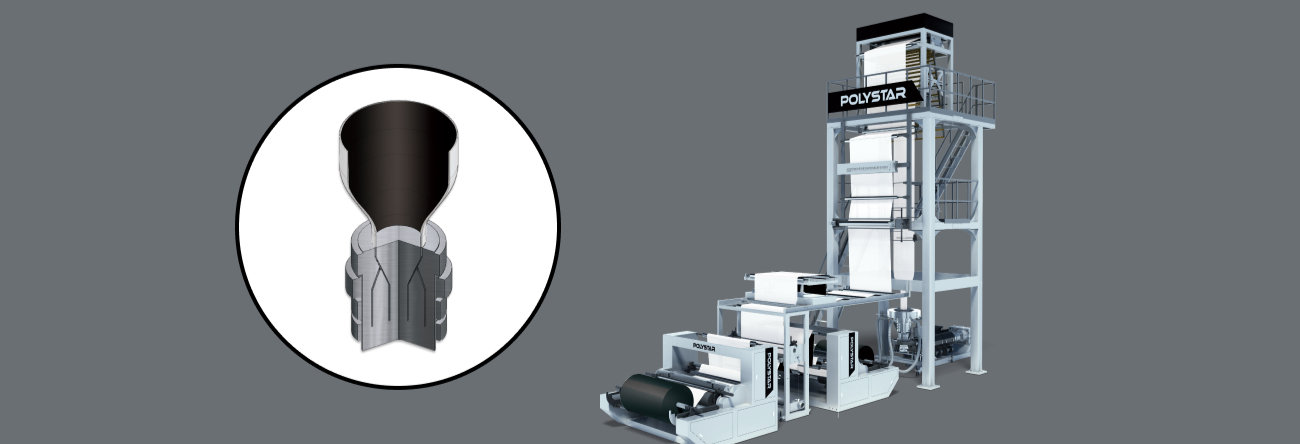

The AB co-extrusion machines can produce film of two different colors or two different properties of material on each side, normally used for agricultural (mulch) film, courier bags and construction film. This two-layer machine typically uses two extruders of the same size for an equal material distribution to A and B layers.

( AB Co-extrusion blown film machine )

What is ABA co-extrusion machine?

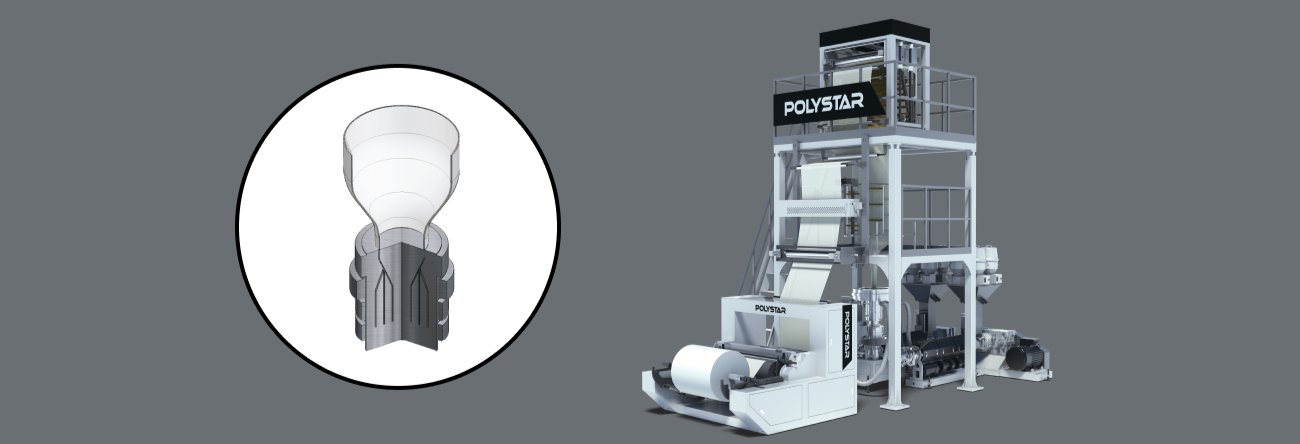

The ABA machine on the other hand, produces a “3-layer” like structure using 2 extruders of two different sizes. The bigger extruder is used for the middle (B) layer which can produce up to 75% of the film composition, while the smaller extruder covers the surface of the finished film using lesser amount of material.

( ABA 3 Layer Co-extrusion )

The comparison between AB/ABA

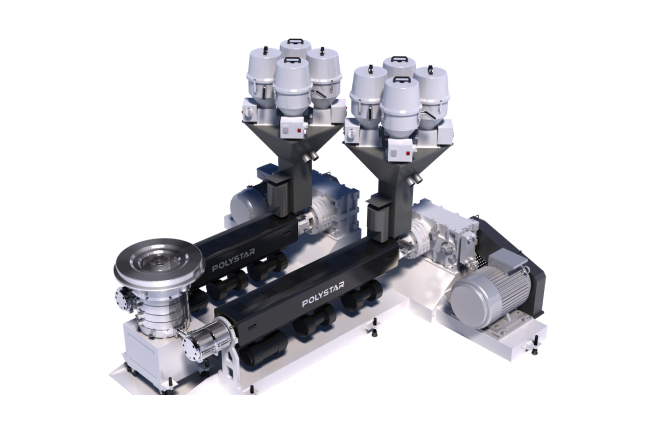

Compared to single-layered machines, both AB and ABA co-extrusion lines produce stronger film with higher tear resistance thanks to a multi-layered film structure.

AB and ABA can also be a more economical option for ABC co-extrusion machines for some applications, achieving the same results while saving on machine investment and electricity cost.

-

( AB/ABA co-extrusion )

( AB/ABA co-extrusion ) -

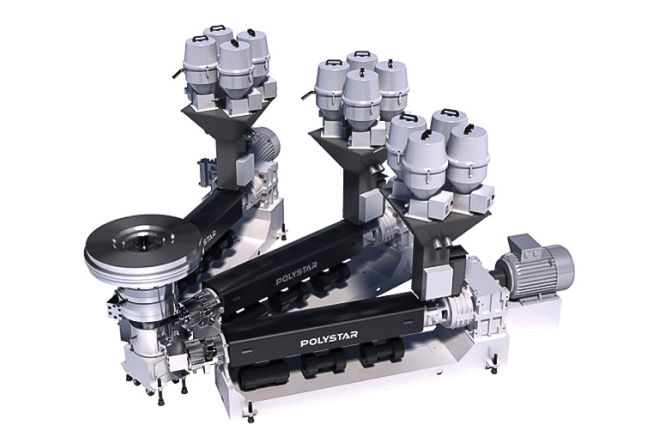

( ABC co-extrusion )

( ABC co-extrusion )

About the Author

Jack Lin

Sales ManagerJack has visited and spoken to hundreds of POLYSTAR machine users around the world over the last 10 years. Having collected practical information on customer feedback and user experiences, he enjoys sharing the advantages and disadvantages of using different types of machines with others, especially coming from the customers' perspectives.