We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Bulk Bag Recycling - Which recycling machine to buy?

Why the Shredder + Extruder + Pelletizer recycling machine is ideal for all kinds of woven bag and raffia production waste?

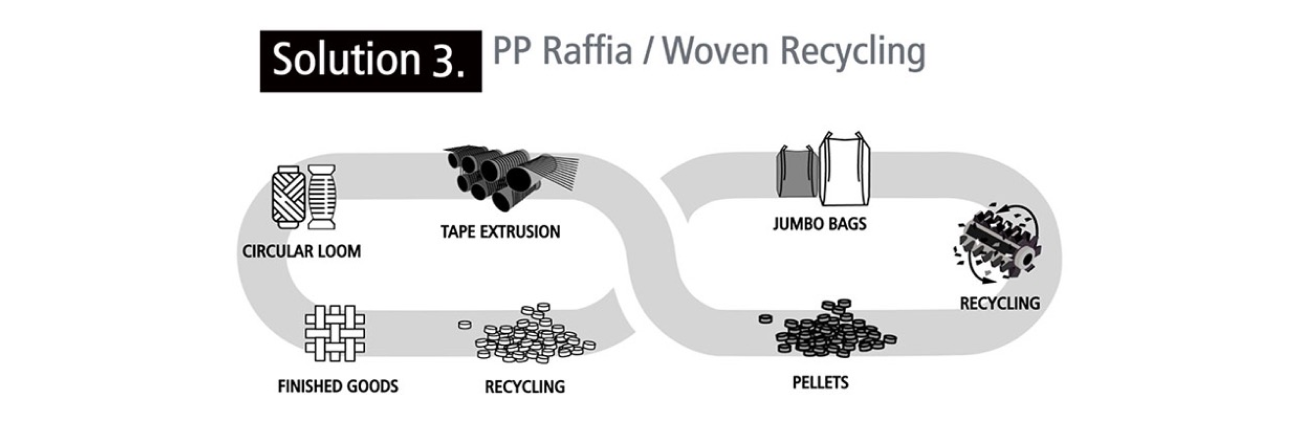

Recycling gives advantages and competitiveness to woven bag production companies if a higher re-using rate of recycled pellets can be added back to tape extrusion lines.

In most cases, producers can use up to 100% of recycled pellets from production waste such as pp raffia, pp bag, bulk bag, and endless tape, while still able to maintaining the strength and quality of the end product (woven bags).

The following factors may make recycling PP bags, bulk bags, woven sacks, non-woven/woven bags, and FIBC bags challenging for post-industrial manufacturers:

-

Difficult to process in one single step

When recycling has to be done in several processing steps due to the size and strength of the material (ex. FIBC, jumbo bags, and bulk bags), it is not cost-effective for the producers in terms of labor, electricity, and occupying too much factory space.

-

Difficult to retain material property (strength and elasticity)

After recycling the material degrades excessively and therefore, the reusability of the recycled pellets back into the production lines is relatively low.

-

Difficult to process heavily printed woven bags

The degassing and screw design of the recycling machine is not ideal for this type of material with an extra amount of ink. (For example, printed PP bags and cement bags.)

(Compared to film waste, it is more difficult to cut and feed raffia waste consistently into the recycling machine for its strength and size. Usually, it has to be done in separate steps.)

One-step, Simply recycle bulk bags and PP raffia

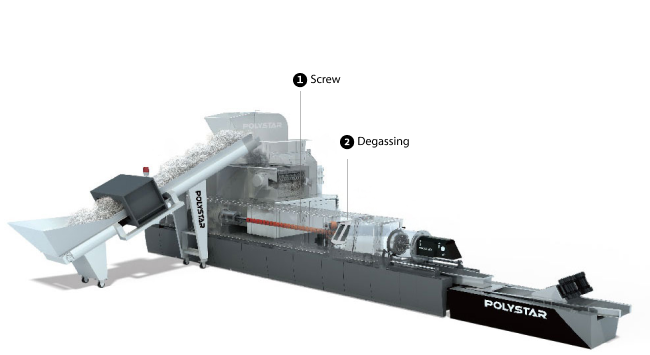

1. One-step process with shredder + extruder + pelletizer all integrated into one simple, easy-to-operate recycling machine.

2. Low processing temperature in the single shaft shredder – higher quality recycled pellets

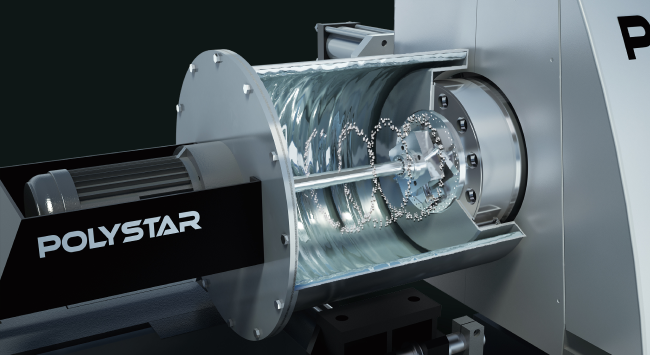

3. Specialized degassing and screw design for processing heavily printed bags

Efficient degassing is another key factor to ensure the pellets are solid (instead of fluffy and hollow in the middle), especially when recycling cement bags or AD*STAR bags that are heavily printed. Recycled pellets from laminated fabric can be used back again in tape line production running at lower line speed.

The optimal screw design can eliminate the problem of material coming out from the degassing (venting) area almost completely, so the machine can operate at full speed with stable production.

Raffia producers who recycle in-house have many advantages

In general, 8% of production waste is generated during the process (from extruder start-up, winding, weaving, bag conversion, and printing). The price of raw material is almost doubled compared to the cost of having it recycled in-house.

It would make sense for medium and large-sized raffia/woven producers (who generate more than 30~40 tones of scraps per month or more) to recycle the production waste internally to reduce production costs.

The PP production waste is too valuable to be wasted regardless of what the market price is at the moment.

Filler masterbatches, additives, and modifiers can also be added during the recycling process to improve the properties even more.

Simple-to-use, plastic recycling pelletizing machine for PP

-

Automatic pelletizing speed adjustment

Prevents pellets from sticking due to the higher melting index of PP material. Produces more uniform-sized pellets without labor intervention.

-

Automatic blade pressure adjustment

Allows the pressure between the pelletizing blades and the die head to remain constant. As a result, there is less machine downtime, easier and faster to change blades.

About the Author

Jack Lin

Sales ManagerJack has visited and spoken to hundreds of POLYSTAR machine users around the world over the last 10 years. Having collected practical information on customer feedback and user experiences, he enjoys sharing the advantages and disadvantages of using different types of machines with others, especially coming from the customers' perspectives.