We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

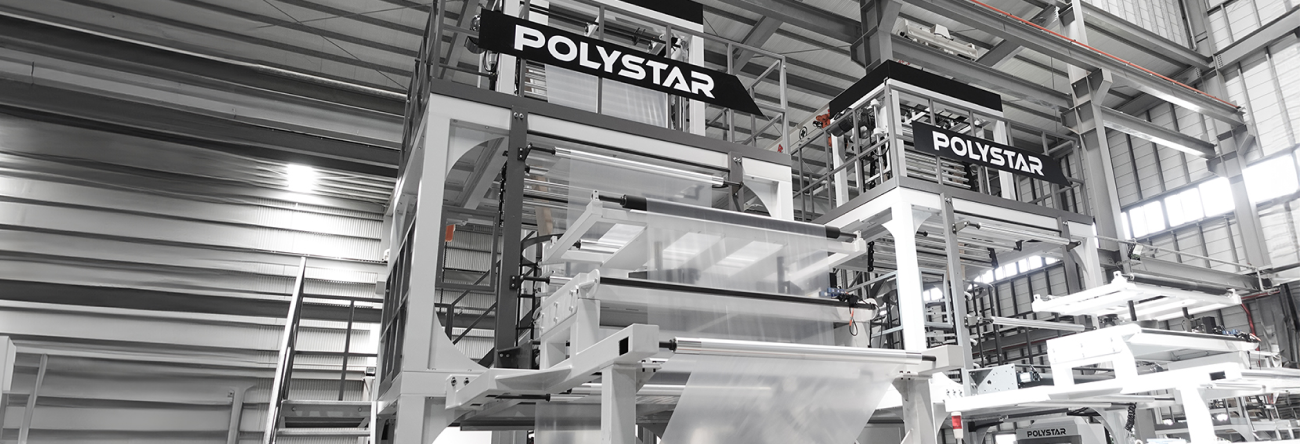

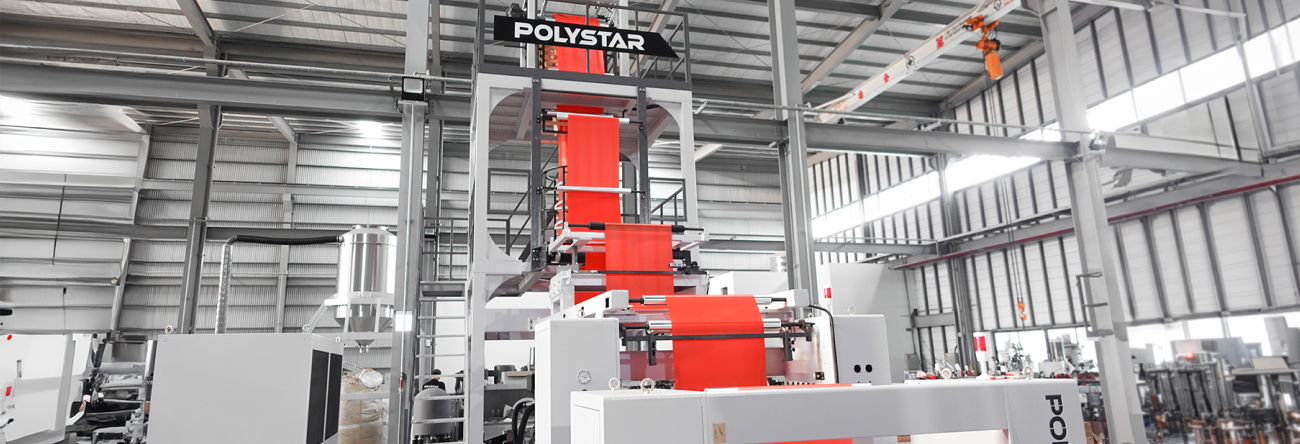

Advantages of Using Monolayer Blown Film Machines for Plastic Packaging

1. Versatility in producing different types of products

One of the main advantages of the Star-X Mono Layer Blown Film Machine is its versatility in producing different types of products. With minor adjustments on the machine or with the help of optional devices, various types of films for plastic packaging products can be produced on one machine.

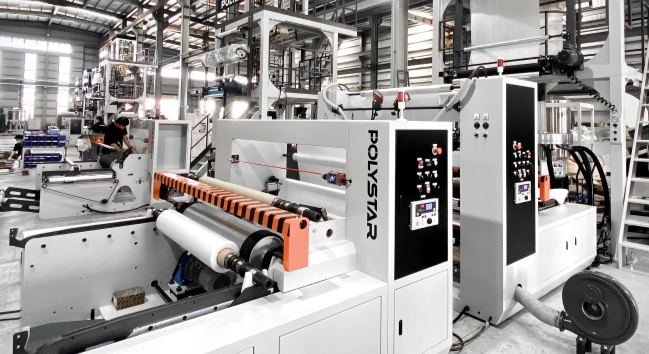

Hot slitting knives option for multiple films on one roll

Back-to-back double winder for flat packaging films

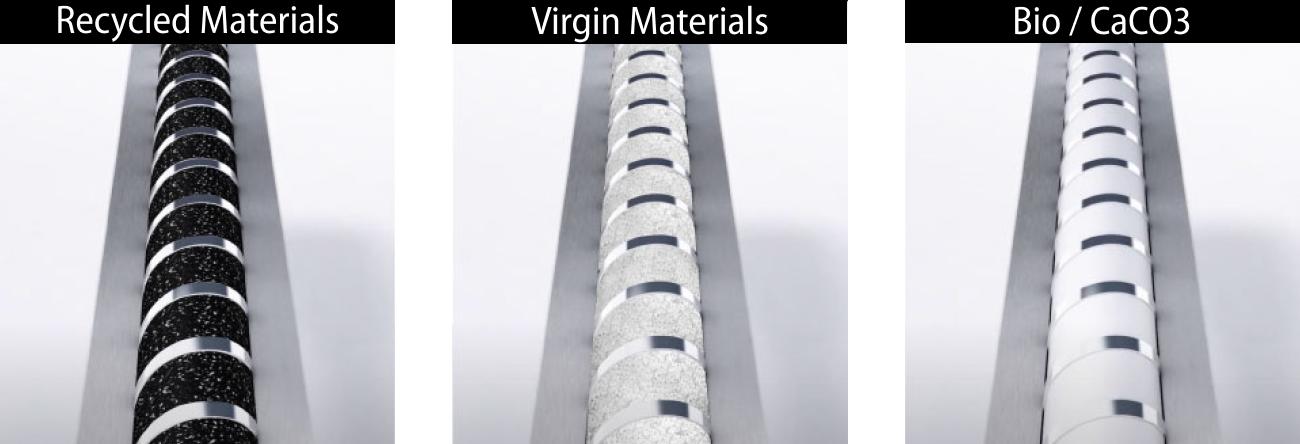

2. Flexibility in working with a variety of materials

The uniquely designed extruder of Star-X monolayer blown film machine provides the advantages of good melting and mixing the HDPE, LDPE, and LLDPE materials (or a blend of them) with masterbatch, additives, and recycled plastic. This allows producers to be more flexible in production and satisfies the market and customer demands. For instance, different material blends for packaging material requirements or a high percentage of recycled material usage in the film content can be achieved easily.

3. Easy operation and maintenance

Monolayer blown film machines are the most suggested to the new starters who plan to produce packaging films. Because they are easier to operate and maintain than multilayer blown film machines. Furthermore, POLYSTAR designs its machines for easy operation and maintenance. Operators can achieve different film thicknesses and widths or even can change to a different type of packaging film production by simple adjustments on the machine.

4. Cost-effectiveness

Producing several different types of packaging films with different material types by using only one monolayer blown film machine provides a certain cost advantage. Furthermore, thanks to the extruder design of Star-X, being able to use a high percentage of recycled materials and CaCO3 in the formula, also helps the film producers to save costs and stay competitive in the market.

In conclusion, monolayer blown film machines are a highly versatile and cost-effective solution for businesses looking to produce plastic packaging products. Ease of use and ability to meet producers’ demands for various types of plastic films, makes them a good choice for plastic packaging film producers.

Learn more

About the Author

Resul Gökpınar

International SalesResul creates up-to-date content based on his experience, gained by solving customers' problems in Turkey and the EMEA market.