We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

About Us

- Simple Operation

- Our Charter Values

- Our History

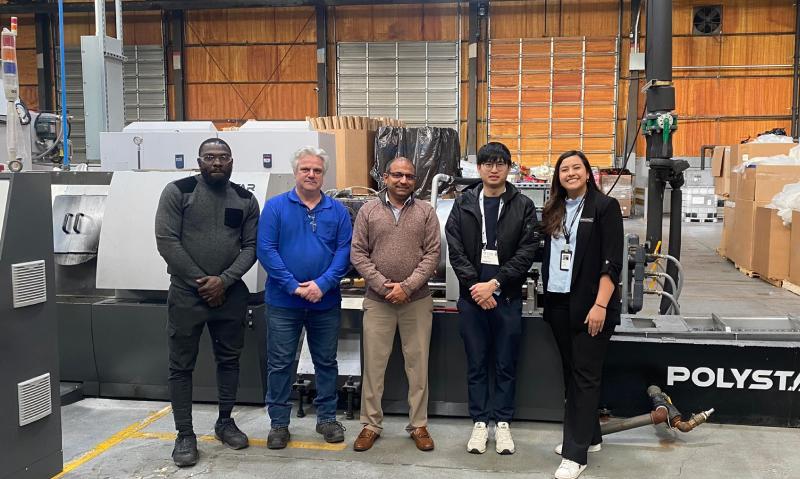

- Successful Stories

- Our Customers

Simple Operation

-

Experience

0

Years

-

All Over

0

Countries

-

Installed

0

Machines

POLYSTAR focuses on the user-friendliness of its machines through continuous re-engineering, making operation extremely “Simple" for its users – Easy operation and maintenance is the reason why POLYSTAR is so popular in the market today.

Our Charter Values

Simplicity

SimplicitySimple in design and easy to operate, our solutions prioritize quality and customer satisfaction. We focus on user interface and customer feedback to continually develop high-quality technology that meets our customers' needs.

Service

ServicePOLYSTAR prioritizes customer service, contributing to its high customer retention rate. Its distributors provide installation, after-sales services, and maintenance in various markets worldwide across multiple economic sectors.

Sustainability

SustainabilityPOLYSTAR's experience in manufacturing recycling and blown film extrusion machines helps promote sustainability by reducing waste and the use of virgin materials in blown film extrusion lines.

Innovative

InnovativeThrough years of innovative manufacturing and design experience, coupled with continuous customer feedback, POLYSTAR has emerged as a global leader in its field, with three generations of technological evolution under its belt.

Our History

Recycling Made Simple - For 35 years on and looking forward

35 years of manufacturing experience and development into a global leader today.

1988

Foundation of POLYSTAR

2010

Brand Name Manufacturer

2013

Simplicity With Power

2017

New Facility and Market Expansion

2023

__24I30C7Xh5.png)