We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

What is Post-Consumer Plastic Recycling? - Advantages and Solutions

Plastic is one of the most widely used materials worldwide, found in everything from food packaging to car parts. As a result, the amount of plastic waste produced is enormous, creating an environmental problem.

This is where mechanical recycling has become a popular solution among plastic producers and recyclers.

What is the process of post-consumer plastic recycling?

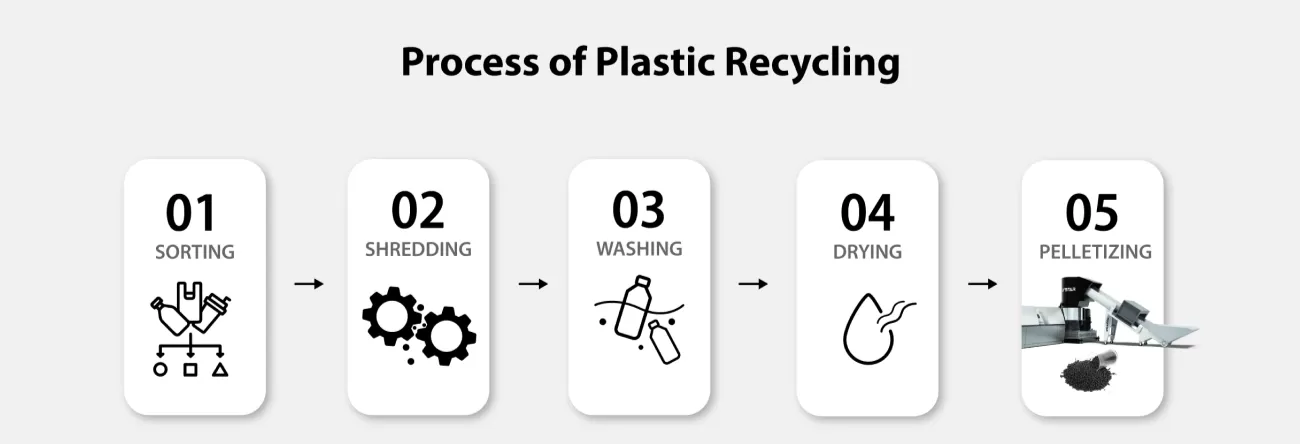

Post-consumer plastic recycling involves several steps in its process, including:

-

Sorting

Sorting is the first step in plastic recycling. This is when plastics are separated by type, that is, by each resin that exists (HDPE, LDPE, LLDPE, PP, among others), by color, and by the form in which they were produced (plastic bags, hard plastics, foam, among others). -

Shredding

After being sorted, plastics will be shredded, each category separately, until they are broken down into small pieces to be put into the next process. -

Washing

After being shredded, plastic waste goes through a washing process to remove impurities and contaminants. -

Drying

Since the plastics will have been washed and will be wet, they will need to be dried to maintain a controlled moisture level of 3-5% for the next step. -

Pelletizing

The final step of mechanical recycling is pelletizing. In this step, the sorted, shredded, washed, and dried plastic waste is converted into pellets. This process is done using recycling machinery that includes an extruder, which melts the plastics that will then pass through a head (which has holes in it), and then be cut into pellets by the blades to obtain the final product, in this case, recycled pellets.

What are the advantages of post-consumer plastic recycling?

Post-consumer plastic recycling not only brings advantages to the environment but also to humanity. Among the advantages of mechanical recycling, we have:

-

Reduction of waste

It reduces the amount of waste that is sent to landfills and that typically takes centuries to decompose (due to the characteristics of different plastics). By recycling plastics, materials will be given another life, and we will avoid them ending up polluting the environment. -

Reduction of natural resource use

With mechanical recycling, pellets that can be put back into production lines will be obtained, thus reducing the use of virgin raw materials. This reduces the environmental impact produced when new materials are extracted. -

Job creation

Mechanical recycling involves different stages, in which a large number of jobs are generated; two stages generate more jobs, one is the collection of plastics and the other is their sorting. Along with mechanical recycling, a positive impact on the economies of countries is obtained. -

Energy savings

In the production (extraction) of virgin materials, large amounts of energy are required, meaning that by recycling mechanically, companies will reduce their costs for pellets as well as electricity consumption. -

Sustainable development

Mechanical recycling leads us to a circular economy, helping to conserve natural resources and care for the environment. This will provide a better and more efficient life for plastics, both waste and virgin materials.

Ideal solutions for post-consumer plastic recycling

-

Post-consumer plastic bags and film waste are made of HDPE, LDPE, LLDPE, and PP.

-

Post-consumer Hard plastic waste made of PE, PP, PS, and ABS.

About the Author

Maria Lopez

Marketing ManagerMaria Lopez is a content marketer at POLYSTAR. She authors in-depth guides that provide solutions to Plastic Producers. Not only to select your machine but also to keep you updated with the new trends.