We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Package Design for Easy Recycling - How to Increase the Recyclability of Plastic Packages?

Tips for designing plastic packages for easy recycling

Designing plastic packages through easy recycling can be achievable in several ways as we mention below. Implementing these elements will be extremely helpful for increasing the recycling rate of packaging plastics and reducing plastic waste.

1. Using mono-material packaging

2. Avoiding mixed materials usage

3. Choosing materials that are easy to recycle

4. Using minimal ink and labels

5. Designing for disassembly

Plastic pelletizer tips to increase the lifecycle of packaging plastics

Plastic pelletizers are the most important components of the recycling process. For recycling packaging plastics several times to boost their circulation in the economy, plastic pelletizers must be efficient and economical.

The following are the crucial points to consider while buying a plastic pelletizer.

1. Consistent feeding for higher and stable yield

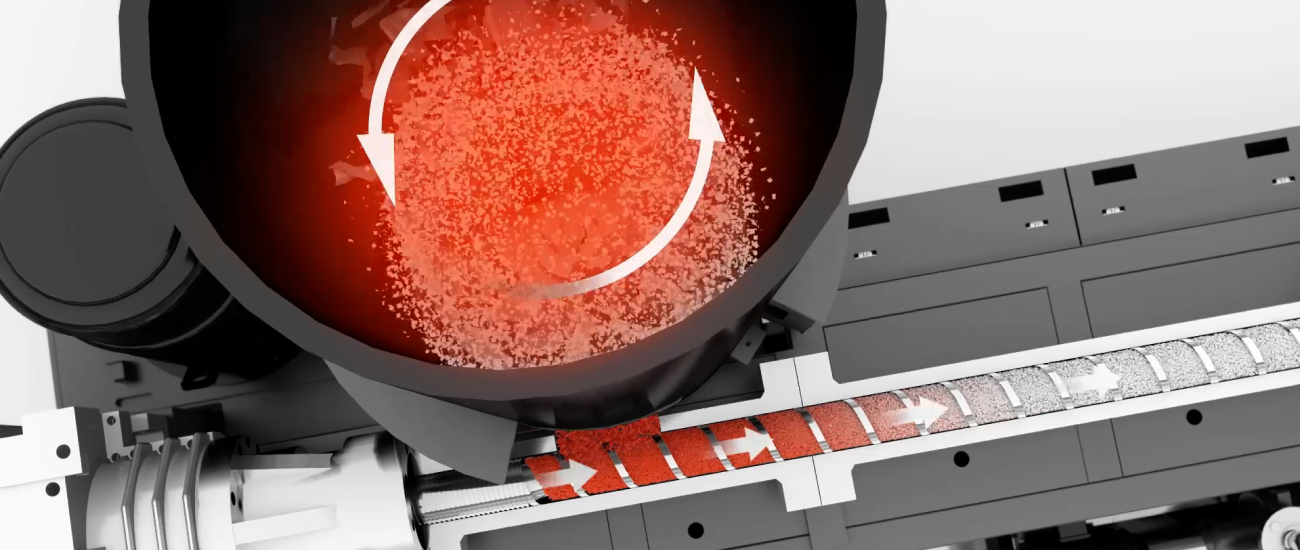

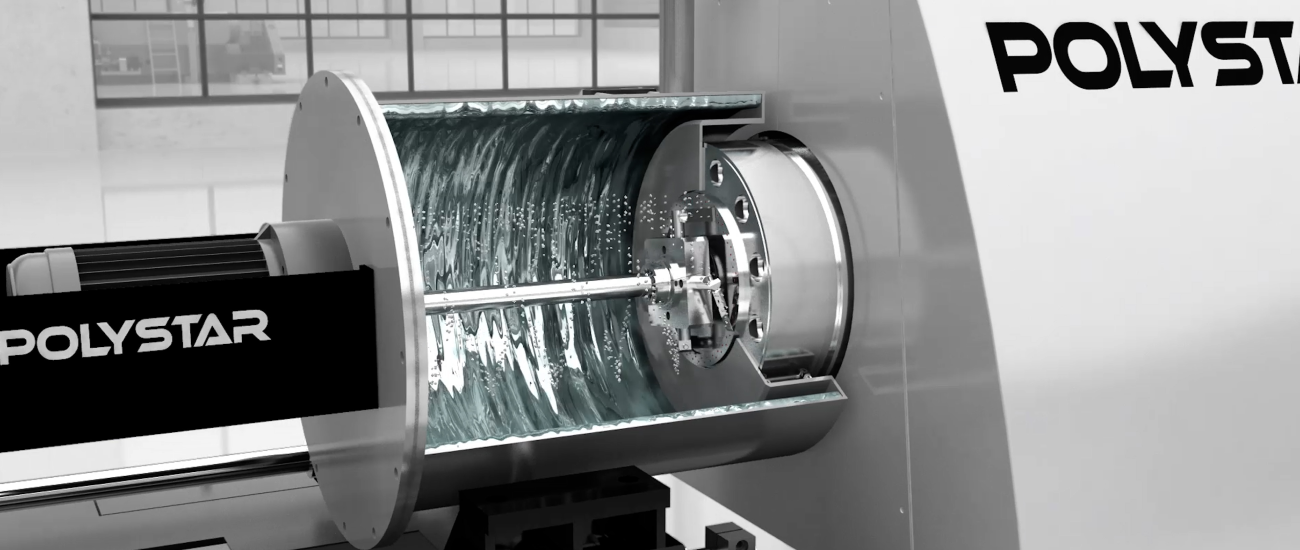

Different types of waste plastic materials require different feeding systems to gain maximum performance from the pelletizer. For instance, POLYSTAR’s cutter compactor integrated plastic pelletizer Repro-Flex is a good choice for processing soft and fluffy packaging plastics such as film and bags. Soft materials fed to this recycling system without pre-cutting will be reduced by size, compacted, and preconditioned by the cutter compactor to increase the feeding amount.

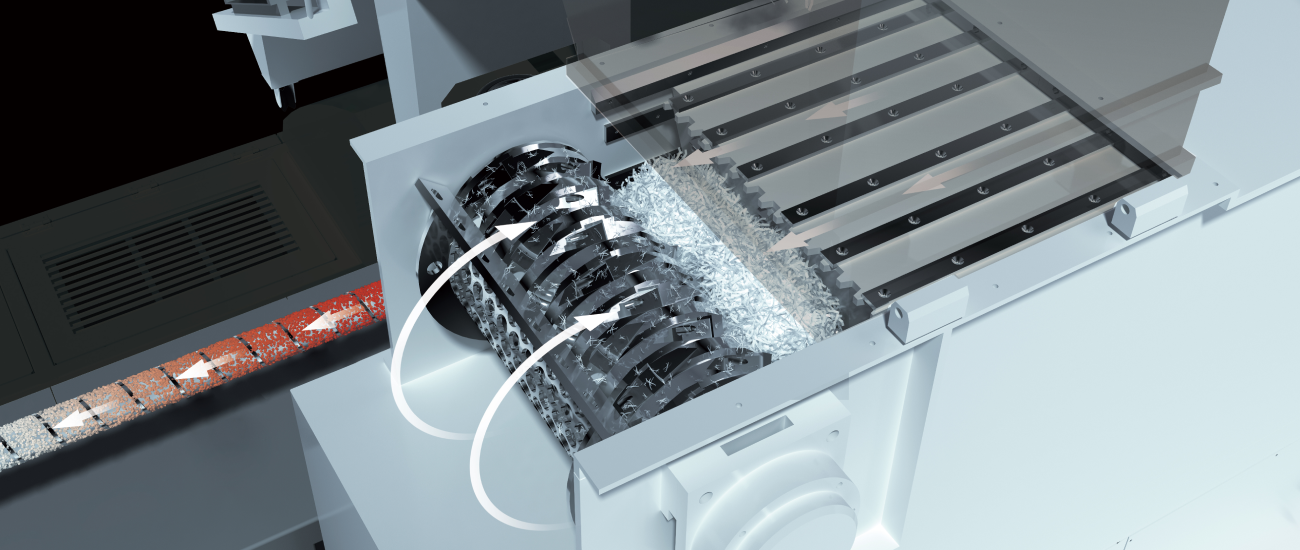

On the other hand, while shredder-integrated plastic pelletizer Repro-One provides a similar solution with its single shaft shredder for uncrushed PP raffia, woven bags, and rigid packaging plastics in terms of feeding efficiency; hopper-feeding plastic pelletizer Repro-Direct provides direct feeding for regrinds and flakes of plastic packaging materials.

2. Efficient degassing for removing ink and gas to increase product quality

The ink, moisture, and trapped air in the material turn to gas in the extruder during recycling. Gas is unwanted in the final pellets because it will decrease the quality of the plastic products made of them. Such as decreasing product strength, and elongation. POLYSTAR solves this problem with single and double-vented (triple-vented for two-stage pelletizers) vacuum degassing system options, resulting in degassed high-quality pellets.

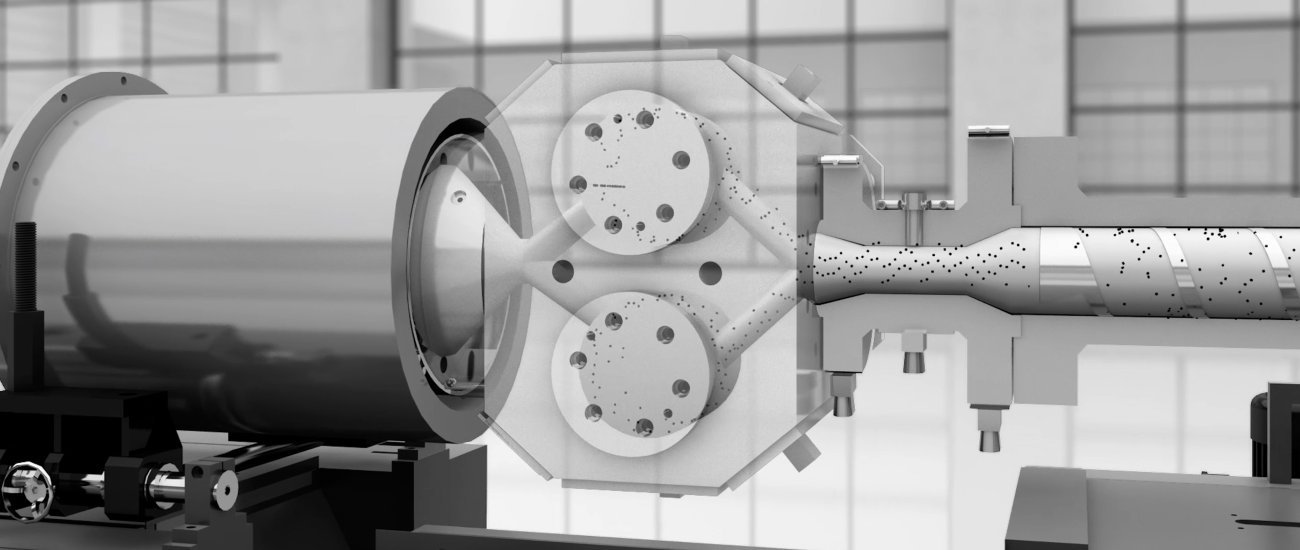

3. Enhanced filtration for the purer recycled pellets

Having a good filtration system to filter out contaminants for obtaining purer recycled pellets is also crucial in plastic recycling. POLYSTAR’s dual piston filtration system provides a wider filtration area, filter changing without stopping the machine, and no material loss during the mesh changing. Upon customers’ need a back-flush filter or a third-party advanced filter integration can be provided.

4. Stable pellet cutting system for highly reusable recycled pellets

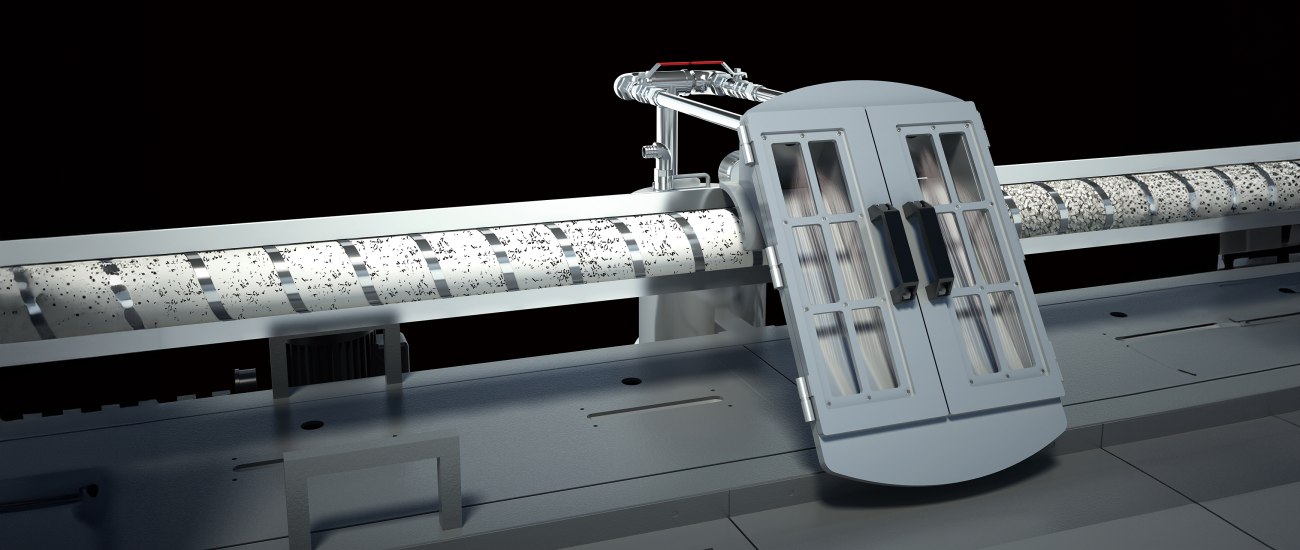

POLYSTAR water ring pelletizer (die head pelletizing) system provides uniform shape and size pellets with automatic pelletizing knife speed and pressure adjustment. In the plastic production by these plastic granules, the heat will be applied to them in the extruders equally and from all sides. This will provide equal melting, smooth material flow, and prevention of plastic overcooking in the extruders.

Conclusion

Recycled pellets obtained from easy-to-recycle packaging materials have higher reusability. Because these purer, less or even not contaminated recycled pellets can satisfy the requirements for plastic production similar to or even the same as virgin materials.

Even though not all packaging plastics are easy to recycle, POLYSTAR provides efficient packaging plastic recycling solutions to increase the lifecycle of the packaging plastics, through continuous re-engineering to make recycling simple for plastic package producers and recyclers.

About the Author

Resul Gökpınar

International SalesResul creates up-to-date content based on his experience, gained by solving customers' problems in Turkey and the EMEA market.