We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

How to Choose the Right Screen Changer Solution?

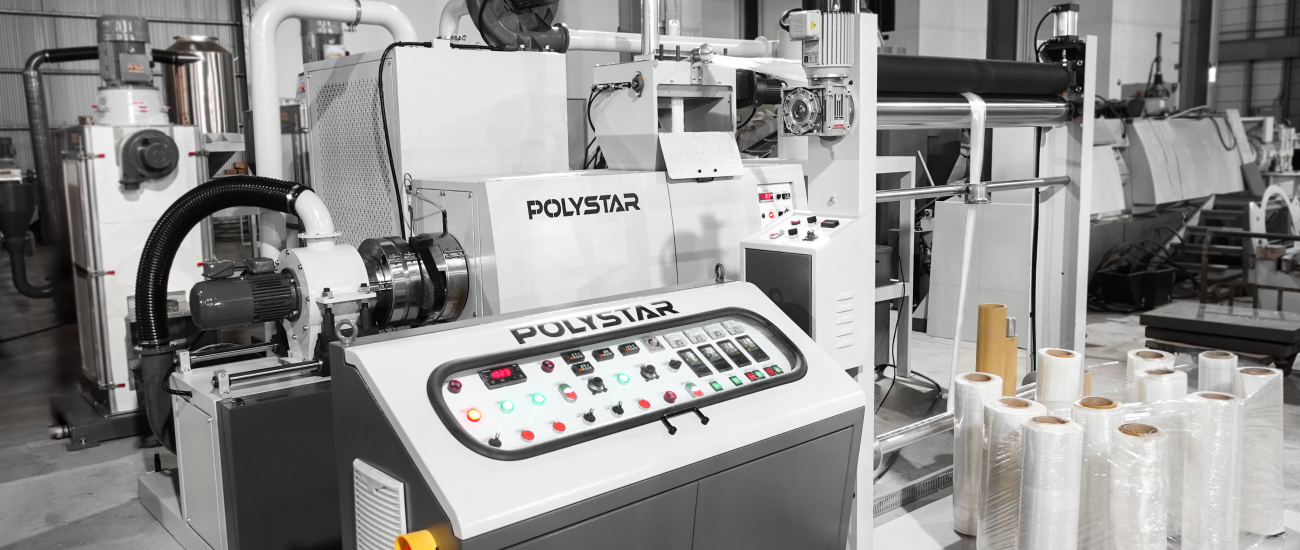

Plastic pelletizing machines provide cutting, extruding, and pelletizing processes in one machine. Within the extrusion process, the degassing and filtration systems play a pivotal role in enhancing plastic quality. In this article, we will focus on the filtration systems that POLYSTAR provides and explain the differences.

Commonly Seen Plastic Wastes and the Sources

| Types | Forms | Sources |

|

|

|

1. Fan-type Screen Changer

Fan-type screen changers feature a smaller screen channel and larger hole sizes that effectively capture relatively larger impurities. The rotary fan blade design is particularly well-suited for plastics with low viscosities, allowing for easy passage through the screen. Due to the smaller filtering area, the screen changing frequency is higher and the durability of the mesh screens are lower.

This system is only applied on our Mini-type in-house plastic pelletizing machine. This model is specifically designed for processing in-house PE films and bags, which typically exhibit minimal contamination levels.

2. Slide-type Screen Changer

Compared to the fan-type screen changer, the slide-type screen changer is designed with a stationary screen plate so that it offers stability for processing plastics with medium viscosity. Moreover, smaller mesh holes enable it to capture finer impurities.

This filtration system is suitable for processing a wide range of impurity levels and viscosities. It reduces the frequency of screen changes, consequently reducing overall maintenance costs. The slide-type screen changer can be applied on all of our water-cooled plastic pelletizing machines, catering to a variety of materials.

3. Dual-piston Screen Changer

Dual-piston screen changers and slide-type screen changers share certain capabilities, such as managing high-viscosity materials and effectively filtering larger impurities. However, dual-piston screen changers offer a bigger filtering area and higher mesh hole density, resulting in prolonged screen durability. They also provide additional benefits including reduced operational interruptions and enhanced final product quality.

The dual-piston screen changer can be seamlessly integrated into all our water-cooled plastic pelletizing machines to maximize recycling performance.

Comparison

|

Fan-type

|

Slide-type

|

Dual-piston

|

|

| Suitable materials | Low to Medium Viscosity Plastics | Medium to High Viscosity Plastics | Medium to High Viscosity Plastics |

| Application | Lower Impurity Levels | Medium to High Impurity Levels | Medium to High Impurity Levels |

| Filtration Efficiency | Effective for Larger Impurities | Effective for Various Impurities | Effective for Various Impurities |

| Maintenance | More Frequent Screen Changes | Moderate Screen Changes | Reduced Screen Changes |

Contact us now to receive solutions for your plastic waste.

Read More

About the Author

Janine Cheng

Marketing AssistantJanine creates engaging content for POLYSTAR’s social media presence, including keeping social media channels updated and brand-focused and seeking ways of connecting with plastic producers and recyclers.